Prospects of Palm Fruit Extraction Technology: Palm Oil

Chien Lye Chew a Chemical Engineering Discipline, School of Engineering, Monash University Malaysia, Subang Jaya, Selangor, Malaysia;b Monash

Improving Sustainability of Palm Oil Production by Increasing

A palm oil mill typically adopts a solvent-free process that uses steam and water for oil extraction. Interestingly, the process to extract the oil from the palm fruitlets has remained relatively unchanged for the past 50 years. Figure 1 shows the block flow diagram of a typical palm oil mill for the production of crude palm oil.

5. PALM KERNEL OIL EXTRACTION Food and Agriculture

MechanicalextractionSolvent ExtractionTraditional Method of Palm KernelextractionScienceDirect

Oil Recovery from Palm Fruits and Palm Kernel - ScienceDirect

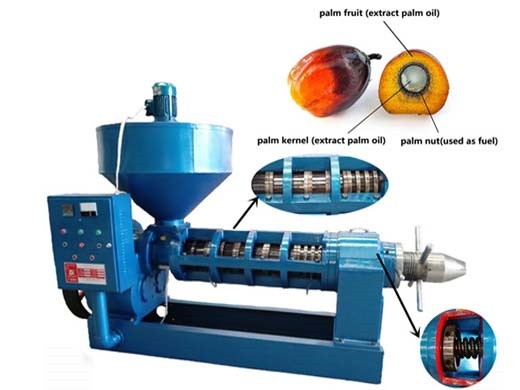

The extraction procedure of oil from the palm kernel is distinct from the palm oil extraction. The palm kernel is the true seed of the palm fruit, hence it shares similar properties and processing or milling equipment with oil seeds such as shea nuts, groundnuts, rapeseed, cottonseed, or coconut copra.

Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of

3. PALM OIL PROCESSING - Food and Agriculture Organization

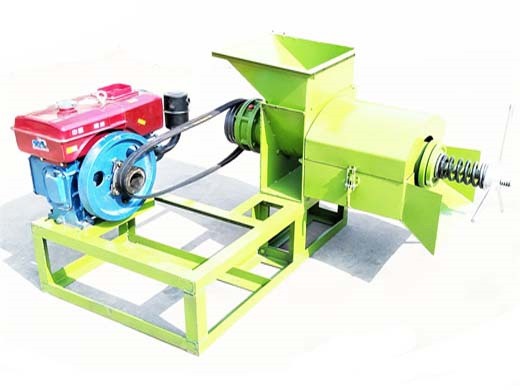

3.1.5 Pressing (Extracting the palm oil) There are two distinct methods of extracting oil from the digested material. One system uses mechanical presses and is called the 榙ry?method. The other called the 榳et?method uses hot water to leach out the oil.

Extraction of Phenolic Compounds from Palm Oil Processing

Oil palm tree (Elaeis guineensis) is the principal source of palm oil and palm kernel oil. It is estimated that roughly 10 % of the pal m tree yields in palm oil w

5. PALM KERNEL OIL EXTRACTION - Food and Agriculture Organization

Palm kernel extraction is a specialised operation undertaken by a completely different set of processors. They are usually better organized as a group and are not as dispersed as palm oil processors. The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying.

1. INTRODUCTION Food and Agriculture Organization

INTRODUCTION. 1. INTRODUCTION. Modern processing of oil palm fruit bunches into edible oil is practiced using various methods, which may be grouped into four categories

Palm and Palm Kernel Oil Production and Processing

The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18?3% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%. The simplified palm oil extraction process is shown in Fig. 8.3. The basic quality parameters for palm products are tabulated in Table 8-B.