Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding

5. PALM KERNEL OIL EXTRACTION - Food and Agriculture Organization

Palm kernel extraction is a specialised operation undertaken by a completely different set of processors. They are usually better organized as a group and are not as dispersed as palm oil processors. The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying.

Prospects of Palm Fruit Extraction Technology: Palm Oil

OER Oil extraction rate PFF Palm press fiber PKO Palm kernel oil POME Palm oil mill effluent PORAM Palm Oil Refiners Association of Malaysia

Palm and Palm Kernel Oil Production and Processing in Malaysia

The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18?3% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%. The simplified palm oil extraction process is shown in Fig. 8.3. The basic quality parameters for palm products are tabulated in Table 8-B.

Palm kernel oil extraction The malaysian experience

Strict quality control right from fruit processing to kernel extraction is necessary to ensure production of good quality oil and by-products. Malaysian palm

Microemulsion-based palm kernel oil extraction using mixed surfactant

The palm kernel oil and palm kernel seed used in this work were donated from Lamsoong Thailand Company and used as received during July to December 2006. 2.2. MethodsTo select the surfactant system to use for extraction, preliminary experiments were conducted to find systems capable of forming microemulsions with palm kernel oil.

5. PALM KERNEL OIL EXTRACTION Food and Agriculture

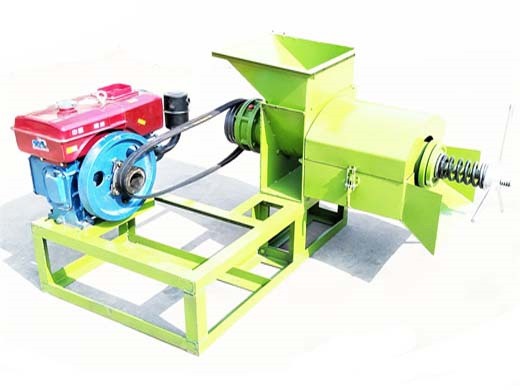

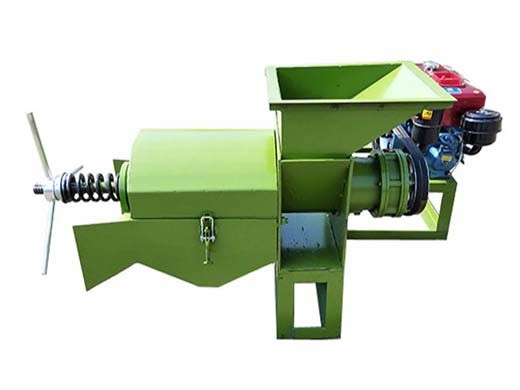

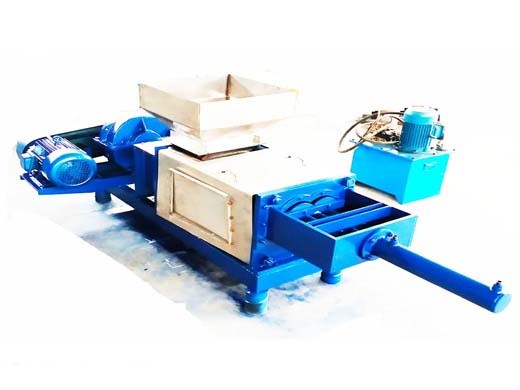

MechanicalextractionSolvent ExtractionTraditional Method of Palm KernelextractionMechanical extraction processes are suitable for both small-and large- capacity operations. The three basic steps in these processes are (a)kernel pre-treatment, (b) screw-pressing, and (c) oil clarification. Diagram 2: Mechanical extractionof palm kernel oil. Line (A) is for direct screw-pressing without kernelpre-treatment; Springer

Palm kernel oil extraction - The malaysian experience

In direct screw pressing, kernels must undergo seed preparation steps of size reduction, flaking and steam conditioning prior to mechanical extraction. Mechanical wear and tear, maintenance expenses and electricity are the major costs. The direct solvent extraction process is used in larger plants.

Palm kernel oil extraction The malaysian experience

Strict quality control right from fruit processing to kernel extraction is necessary to ensure production of good quality oil and by-products. Malaysian palm kernel oil has proven to

Extraction process of palm kernel cake as a source of mannan for feed

Abstract Palm Kernel Cake (PKC) is a by-product of palm kernel oil extraction and found in large quantity in Indonesia. The inclusion of PKC on poultry diet are limited due to some nutritional problems such as anti-nutritional properties (mannan).