Interlocking Stabilized Soil Blocks (ISSB)

Interlocking Stabilized Soil Blocks, also called Interlocking Compressed Earth Blocks (ICEBs), are bricks that are made from mixed soil that can be found on or off the construction site. The soil is usually mixed with

Interlocking Stabilized Soil Blocks (ISSB) - Engineering For Change

Interlocking Stabilized Soil Blocks, also called Interlocking Compressed Earth Blocks (ICEBs), are bricks that are made from mixed soil that can be found on or off the construction site. The soil is usually mixed with cement, water, and other additives to improve its characteristics.

Experimental and numerical study of Interlocking

The stabilized soil was then mixed and hydraulically compressed in a mould under a pressure of some 12 MPa using equipment supplied by Hydraform

Makiga Stabilized Soil Block Press | Engineering For Change

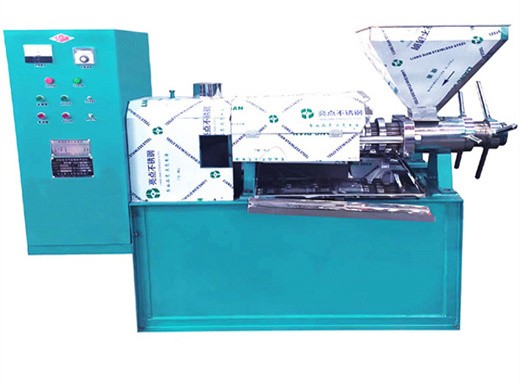

The Stabilized Soil Block (SSB) Press by Makiga is a manual press machine that produces stabilized soil blocks (SSB). This can be various shapes, interlocking ( ISSB) or non-interlocking. Makiga proposes that the press can produce blocks used for affordable housing, water storage and sanitation solutions.

Makiga Stabilized Soil Block Press

The Stabilized Soil Block Press by Makiga is a manual machine that can be used to press 500 bricks in a day. There are four different machines for various block shapes: straight interlocking blocks, wide straight

Main Home - Makiga Engineering

Makiga Engineering Services Ltd. Makiga Engineering Services Ltd is a private sector company committed to offering low cost, eco friendly and durable construction using appropriate building technologies. The heart of our operation rests on our unique manual machine presses for making interlocking stabilised soil blocks (ISSB) for building.

Experimental and numerical study of Interlocking

The stabilized soil was then mixed and hydraulically compressed in a mould under a pressure of some 12 MPa using equipment supplied by Hydraform

Finite element modelling of interlocking stabilized laterite soil block

Interlocking soil blocks (dimensions 220 mm long 脳 220 mm wide 脳 120 mm high) were made of laterite soil consisting of 25% fine gravel and 75% sand. Pozzolanic cement (PC), hydrated lime (L) and rice husk ash (RHA) were used in combinations as stabilizers. Tests were conducted on individual blocks in accordance to KS 02 1070 [ 22 ].

Interlocking Stabilized Soil Blocks Global Ecovillage

Steps: 1) Take soil/sand/clay and mix it with the cement. Rule of thumb is a ratio of 1 (cement)/6 (soil). See the UN-HABITAT link for simple techniques on establishing the

Interlocking Stabilized Soil Blocks - Global Ecovillage Network

How to make Stabilized Interlocking Soil Blocks Materials required: 1: A stabilized soil block machine (manual machine) 2: Soil: Clay soil, murrum soil, sand?But not black cotton soil. 3: Cement/lime/sawdust/wood ash. 4: Water 5: Manpower Steps: 1) Take soil/sand/clay and mix it with the cement. Rule of thumb is a ratio of 1 (cement)/6 (soil).