Palm oil milling equipment and machinery | Alfa Laval

Based around our advanced, 3-phase PANX decanter, Alfa Laval D3 PRO is the industry’s only all-in-one processing solution that can process undiluted crude palm oil with consistent performance, even at high capacities. D3 PRO requires no dilution water,

Palm oil milling equipment and machinery | | Alfa Laval

Our portfolio of equipment and palm oil mill machinery includes two- and three-phase decanters for efficient separation performance; nozzle separators for separation of sludge and increased oil recovery potential; purifier solutions based on a solids-ejecting disc stack separator; highly efficient cyclone desanders for the removal of fine sand

Palm Oil in Turkey OEC The Observatory of Economic

ECONOMIC COMPLEXITY of Turkey 0.61 Rnk 42 / 131. 2021. PRODUCT COMPLEXITY IN Palm Oil -2.07 Rnk 1008 / 1029. image credits. Latest Trends. Historical Data.

3. PALM OIL PROCESSING - Food and Agriculture Organization

Large-scale plants, featuring all stages required to produce palm oil to international standards, are generally handling from 3 to 60 tonnes of FFB/hr. The large installations have mechanical handling systems (bucket and screw conveyers, pumps and pipelines) and operate continuously, depending on the availability of FFB.

3. PALM OIL PROCESSING Food and Agriculture Organization

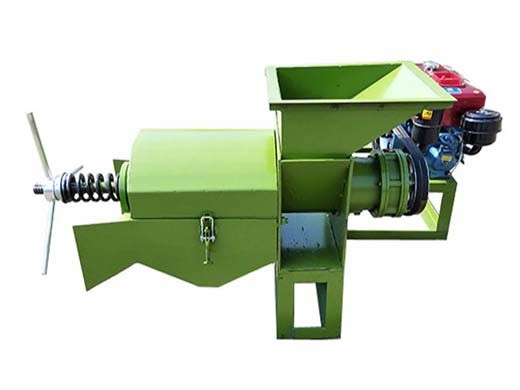

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly

Myande provides equipment and turnkey plants for oilseeds, oils & fats

Myande Group is Asia leading supplier of complete equipment and turnkey plants for oilseeds, oils & fats, starch & derivatives processing, evaporation crystallization and fermentation industries.

Turkish Palm Oil Suppliers and Manufacturers

Get latest factory price for Palm Oil. Request quotations and connect with Turkish manufacturers and B2B suppliers of Palm Oil. Page 1 Help Contact Customer Support

Palm Oil | How It's Made - FoodUnfolded

Degumming, bleaching, and deodorising are typical refining activities. 5 After refining, the final step of the palm oil production process may be to fraction (separate) the oil into liquid and solid phases. Uses in The Food Industry Palm oil is widely used in the food industry because of its low production cost.

Solvent Extraction Myande Group

Miscella is the liquid fraction obtained through solvent extraction. It consists primarily of oils, volatile solvents, and entrained meal powder. After removing impurities, miscella is

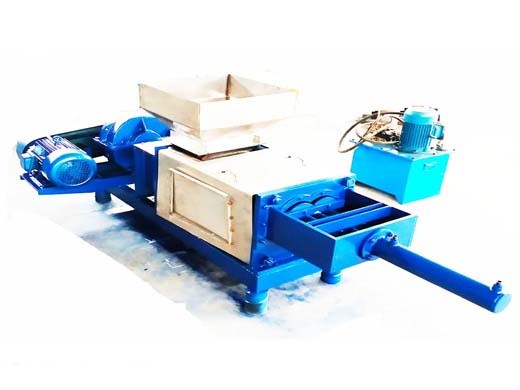

Palm Oil Mill Processing Machines - Palm Oil Mill Machine Leading

Palm oil mil process of drying: continuous Vacuum drier with the oil out of the water, the water can be reduced to 0.1%. 9.Palm oil mil process of depericarper (splitter): through floating dry processing the fruit core and fibers separated. Fiber and other lighter stuff are blown appearance. 10.Palm oil mil process of crushing (crusher): stone