Formation, characterization, and potential food application

The expeller-pressed (EP) corn germ oil oleogels were prepared using rice bran wax (RBX) at different concentrations (3, 5, 7, and 9 wt%). Their structural

Formation, characterization, and potential food application

The expeller-pressed (EP) corn germ oil oleogels were prepared using rice bran wax (RBX) at different concentrations (3, 5, 7, and 9 wt%). Their structural properties, including color, hardness, thermal behavior, rheological property, and crystal structure were evaluated.

WP Corn Germ Anderson International Corp

EXPELLER® PRESSING OF WET PROCESSED CORN GERM Anderson International Corp 4545 Boyce Parkway Stow, OH 44224 216‐641‐1112 Corn oil, as a product of the

Formation, characterization, and potential food application

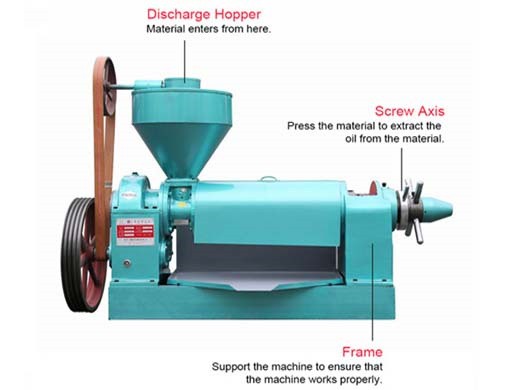

Expeller-pressed corn germ oil was prepared using a low-shear screw oil expeller (Model DD 85 G-1, Komet IBG Monoforts, M枚nchengladbach, Germany). This expeller was equipped with an electrical-resistance heating ring attached around the outer surface of the press head and was powered by a 3-kilowatt driver with speed恈ontrol gearbox.

screw corn germ oil expeller wholesale in lesotho

Expeller? pressing of wet processed corn germ Engormix Type: Automatic multifunctional screw oil press Production Capacity: 100kg/h-5000kg/h-100% Dimension(L*W*H):

WP Corn Germ - Anderson International Corp

Expeller cake will have residual oils of from 5.5 to 7.5% depending upon the original purity of the germ. Under optimum conditions of operation the Expeller Press will discharge between 800 and 1200 pounds of cake per hour depending to a large extent upon where the purity of the germ might lie in the range of 55% to 45%.

Corn / Maize Germ Oil Mill Plant Oil Expeller

Here we have listed some of the basic machinery required for Corn Germ Oil Mill Plant including 1. Seed Cleaner 2. Oil Expeller / Oil Press 3. Filter Press with Pump 4. Steam Boiler 5. Bucket Elevator 6. Screw Conveyor 7. Oil storage tanks 8. Control PanelScienceDirect

Corn Germ - Anderson International Corp

Discover how to reap significant benefits from this byproduct by using an extrusion system to release the oil trapped inside the germ. Learn the refining process and the four basic steps for wet corn milling: steeping, degerminating, extrusion, and oil pressing.

Corn Germ an overview ScienceDirect Topics

Besides cornstarch and corn oil as the main products of wet milling process, the process generates multiple coproducts of corn gluten feed, corn gluten meal, corn germ meal,

Corn / Maize Germ Oil Mill Plant - Oil Expeller

Oil Expeller / Oil Press Oil content of Corn / Maize germ produced by Wet Milling is as high as 50% and that by Dry Milling is about 25%. 2 Stage pressing is required for wet milled corn germ and single stage pressing is required for dry milled corn germ.