A Review on the Fundamentals of Palm Oil Fractionation

Monash Industry Palm Oil and Education Research Platform, Monash University Malaysia, Jalan Lagoon Selatan, Bandar Sunway, Subang Jaya, Selangor,

Dry Fractionation - AOCS

Palm oil is by far the most fractionated oil in the world. Given the broad spectrum of triglycerides and also its naturally high amount of palmitic acid that gives a fat 榖ody?at room temperature, the separation of palm oil into sharply defined fractions usually happens in a multi-stage process (Fig. 7). Figure 7. Multistage fractionation

A Review on the Fundamentals of Palm Oil Fractionation

Monash Industry Palm Oil and Education Research Platform, Monash University Malaysia, Jalan Lagoon Selatan, Bandar Sunway, Subang Jaya, Selangor,

Fractionation and Winterization of Edible Fats and Oils

A operationshisyear.quantityof2,700 tons ofcrude palm oiland 1,300 tonsofAnother10palm oil fractionationpl inntsMalaysia are coconutoilwill befractionatedandrefined for the produc-nowready foroperationorwill becompletedin hecoursetion f1,000 tons ofmargarineblend,2,400 tons of cook-ofthis year.

Palm oil fractionation Kellens 2007 Wiley Online Library

Modification techniques like fractionation, interesterification (chemical or enzymatic) and hydrogenation allow proposing a large range of new fatty products. At a

Palm oil fractionation - Kellens - 2007 - Wiley Online Library

The oil processing industry uses dry fractionation to extend the application of a whole variety of fatty matters as well as to replace, fully or partially, the chemical modifications. Due to the continuous developments of the dry fractionation process, a whole variety of products normally produced by solvent fractionation can now be obtained

Palm Oil Fractionation

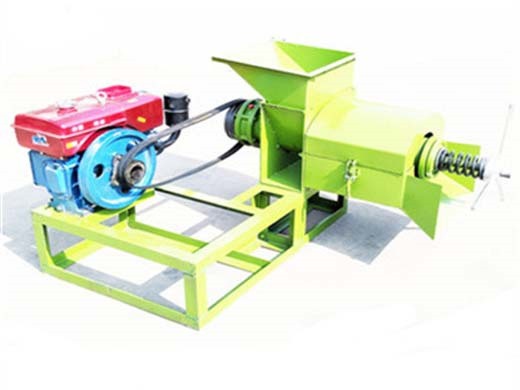

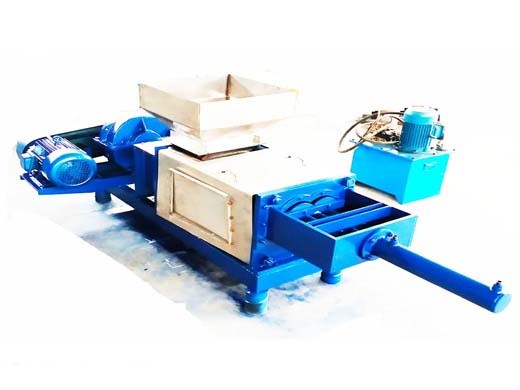

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will

SUSTAINABLE PRACTICES OF AN EDIBLE OILS REFINING COMPLEX

An official publication of the Malaysian Palm Oil Counc il (MPOC) Journal of Oil Palm , Environment & Health 20 20 , 11 : 42 - 56 doi:10.5366/jope. 2020 .05 SUST AINABLE PRACTICES OF AN EDIBLE OIL S

Palm Oil Dry Fractionation process 2 from Desmet Ballestra

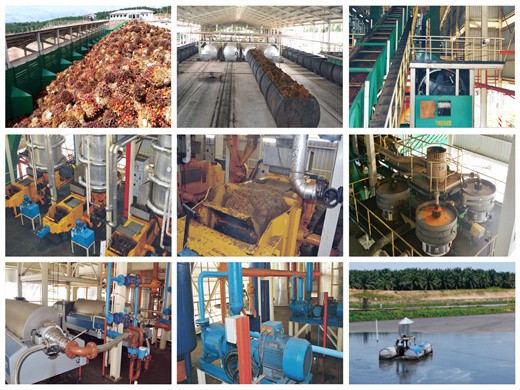

Physical refinery The process flow diagram for palm oil physical refining is shown in Fig. 2. The physical refinery is where CPO, that is received from the mills, is processed. The

Palm Oil Fractionation

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0鈩?to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.