Soybean oil extraction with ethanol from multiple-batch

The batch extraction sequence assumed to experimentally reproduce the 3-stage countercurrent extraction is demonstrated in Fig. 1 a, in which each circle corresponds to an experimental extraction step.Letters S, F, E i ’, and R i ’ represent the pure solvent,

Effect of feed particle size and solvent flow rate on soybean oil

The influence of particle size and solvent flow rate on the kinetics of oil extraction from soybean (eight fractions from 0.433 to 0.122 mm) was studied using hexane, simulating commercial percolation type extractor. The reduction in particle size from 0.433 mm to 0.141 mm showed an increase in the oil yield. However, further reduction to 0.129 mm and 0.122 mm affected the yield due to bed

High intensity ultrasound-assisted extraction of oil from soybeans

Oil yield as a function of extraction time for soybean variety TN 96-58 using high-intensity ultrasound at ultrasonic intensities of 0, 16.4, 20.9 and 47.6 W/cm 2 using

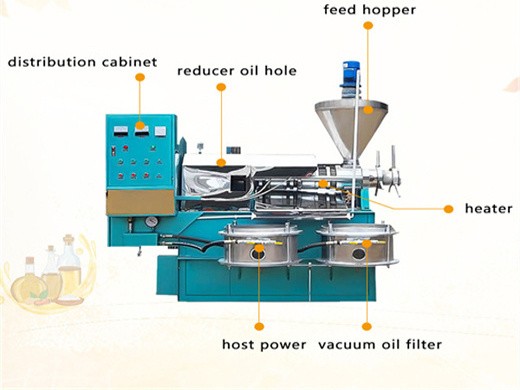

Performance evaluation of continuous screw press for extraction soybean oil

The moisture content of the soybean used for the experiment was 10.7% (w.b). The mean oil yield, expelling efficiency and extraction losses ranged between 6.61 and 14.22%, 32.26卤0.39% (50 o C

Performance Evaluation of Continuous Screw Press

extraction of oil from soybean have been identified as a major bottleneck to its utilization. Soybean is considered as one of most important cereal grains

Cold pressed soybean oil - ScienceDirect

Kania et al. (2004) reported that solvent extraction of soybean oil yielded higher total tocopherols content (1448 mg/kg) than cold pressing (1358 mg/kg), and the refining process led to the loss of 伪-tocopherol by 37%, 尾-tocopherol by 56%, 纬-tocopherol by 17%, and 未-tocopherol by 34% in solvent-extracted soybean oil.

Soybean oil extraction and separation using switchable or

Replacement of hexane with a solvent less prone to losses is becoming a priority for the industry. Supercritical CO2 (scCO2) could be used but requires 500 bar for the most energy-efficient extraction of soy oil from soybeans (i.e. minimum energy cost per kg of extracted oil).2,3 Soybean oil is miscible with many other low polarispringer

Soybean Oil Extraction and Processing | SpringerLink

Abstract. Soybeans are the dominant oilseed in both U.S. and world markets. During a typical year soybean production comprises over half the worldwide oilseed production ( Anonymous 1995 ). However, according to Dutton (1981) in the early 1940s, soybean oil was considered a poor quality oil, not suitable for food use, and more appropriate for

Soybean Oil Extraction and Processing SpringerLink

Soybeans are the dominant oilseed in both U.S. and world markets. During a typical year soybean production comprises over half the worldwide oilseed production ( Anonymous

Impact of polar bio-solvent, particle size and soaking time on

In this study, an efficient and green technology i.e. microwave-assisted extraction (MAE) was applied to extract the crude oil from black soybean (Glycine max var). During experiment, effect of three independent variables, solvent type (iso-propanol, ethanol, iso-propanol + water and ethanol + water), particle size (