Advances in bio-oil extraction from nonedible oil seeds

Bio-oil production from microalgal biomass is a consecutive process that consists of the cultivation, harvest, oil extraction, and conversion of algal lipids into

Optimization Methods for the Extraction of Vegetable Oils:

The three major steps involved in solvent extraction are oilseed cleaning and conditioning, oil extraction, and separation of the miscella. Crude oil and meal quality depend mostly on type of solvent used, reaction temperature, and type of pretreatment given to the oilseed [ 25, 26 ].

Green solvents and technologies for oil extraction from

Aqueous extraction involves water as a medium to extract the oil from oilseeds. It is well known that the lipid molecules are amphipathic in nature and the water soluble components diffuse into water which culminates into emulsion formation [21]. The emulsified oil in water can be de-emulsified by changing the temperature or deploying enzymes. Henc...mdpi

Green solvents and technologies for oil extraction from

Oilseeds are crucial for the nutritional security of the global population. The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n-hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a

Optimization Methods for the Extraction of Vegetable

The 225 W microwave power, 15 mL/g solid/liquid ratio, and 20 min extraction time were the optimum conditions necessary to obtain a yield of 87.4% ±

(PDF) Cold press in oil extraction. A review - ResearchGate

Initially, a classical Soxhlet approach was used, based on n-hexane (operative temperature of 69 ?C), tested extraction times of 2-6 h, and chose 4 h as the best compromise between time/energy...

(PDF) Cold press in oil extraction. A review ResearchGate

Cold press in oil extraction. A review December 2018 DOI:10.24263/2304-974X -2018-7-4-9 Authors: Büşra Çakaloğlu Ebcim Ege University

Cold press in oil extraction. A review

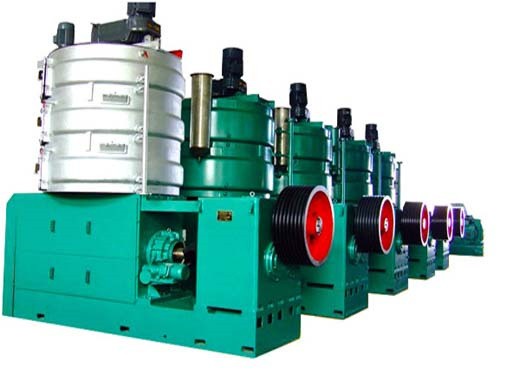

for oil extraction from oilseeds with oil content below 20% [4]. Pressure is used in the separation of the mentioned phase separation. And depending on whether or not the temperature is applied, it is called hot or cold press extraction [5]. Cold press machine has one inlet that seeds were feed and two exits that obtained oil

Processing and Food Uses of Peanut Oil and Protein

A ton of shelled peanuts increased oil yield to 100–115 gallons and 1100–1200 pounds of cake at 40–50% protein. Data ( Dean and Sanders, 2009) on the

Overview of the soybean process in the crushing industry

In a modern and efficient extraction plant, a residual oil content 鈮?0.5% for soybean meal is expected. The first step for an efficient solvent extraction is a good preparation process; its