Dewaxing systems Alfa Laval

Dry dewaxing also has its limitations, such as a maximum wax content of 900 ppm for the feedstock to pass the 24-hour cold test. To achieve effective wax removal, many edible oil producers now combine wet dewaxing

Dewaxing systems | Alfa Laval

The dry dewaxing process involves mixing the oil with filter aid powder, followed by cooling and maturation. Slow cooling ensures that any crystals formed do not prompt blockage of the filter. Dosing the filter aid powder acts as a control for seeding for crystal growth.

A Modern Dewaxing Technology For Edible Oils Refining

The isoparaffins structures formation improves the dewaxing yield at 90.7% reported on the miscella crude oil with 270 ppm waxes content with an almost double

Refining Vegetable Oils: Chemical and Physical Refining - Hindawi

Secondly, the oil is cooled slowly to 283?88 K (10?5 C). Ideally, the chilled oil is held for several hours at this temperature. In the third step, after finishing the crystallization, the cooled oil is pumped into a filter machine to separate the wax from vegetable oil. The filtration yields a clear liquid oil and the by-product waxes

Degumming systems Alfa Laval

Get tastier edible oils and longer shelf life with our degumming process system that remove hydratable and non-hydratable gums —phospholipids, proteins, carbohydrates, nitrogen

Oil Dewaxing Winterization,Fractionation - Oil Mill Plant

Conventional dewaxing is the common oil dewaxing method with the working principle of freezing and then mechanically separating oil & wax without any auxiliary means, the separating methods are usually pressure filtration, vacuum filtration, and centrifugal separation. Conventional dewaxing is the simplest oil crystallization and filtration method.

Dewaxing systems Alfa Laval

At the same time, wet dewaxing can process oil with wax content of up to 2000 ppm; however, this impacts the results of the cold test. Dry dewaxing also has its limitations,

Dewaxing Process, Oil Dewaxing Process, Sunflower Oil

Dewaxing is performed only for high wax containing oils such as Sunflower Oil, Rice Bran Oil, Corn Oil etc. Tinytech Dewaxing Plants are incorporated with intrinsically designed Crystallizer Equipments which are specially made of very slow cooling with continuous agitation for better heat transfer.

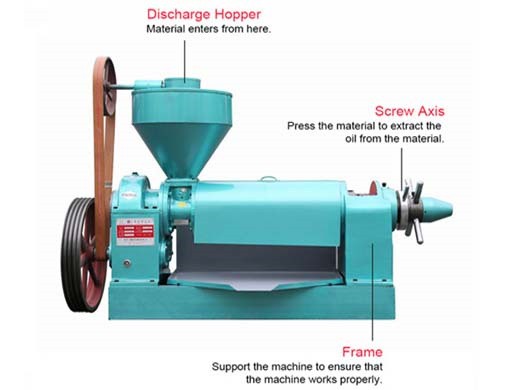

Canola Oil Processing Plant Process, Machinery, Cost

For processing Canola seed, the basic equipment we need are Seed Cleaner, Seed Cooker/Kettle, Oil Press, Filter Press, Steam Boiler, Screw Conveyors & Bucket Elevators. The following are steps involved in Canola Oil Extraction Plant:oil-refinery

Canola oil extraction plant - vegetable oil extraction machine

We have been specialized in canola oil extraction plant since 1967. We can offer whole line of canola oil extraction plant with turnkey service, capacity from 10 to 6000TPD . For special capacity, our engineers can help you design and install canola oil extraction plant according to your real conditions.