Palm Oil Industry—Processes, By-Product Treatment

It provides job opportunities to at least 3 million people along its beneficiation chain and contributed RM37.7 billion to Malaysia’s Gross Domestic Product

Palm oil: Processing, characterization and utilization in the

The most common methods of palm oil extraction are either the 榳et?or the 榙ry?processes. In the 榳et?process a liquid, usually water, is used to extract the oil from the milled palm fruits. Hot water or steam is used to leach out the oil from ruptured oily cells of the palm fruits.

Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of

Prospects of Palm Fruit Extraction Technology: Palm Oil

However, the process technologies and the quality of palm oil produced have remained stagnant for the past decades. This paper reviews the latest development in the process technologies that can be applied in the palm oil milling process to improve the sustainability and efficiency of palm oil production, as well as the quality of the oil produced.

3. PALM OIL PROCESSING Food and Agriculture Organization

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly

(PDF) Palm Oil Milling & Processing Handbook - ResearchGate

Malaysian Palm Oil Board Abstract This new version of the handbook takes into account the latest developments in milling and processing activities. It incorporates the latest technologies for...

(PDF) Palm Oil Milling & Processing Handbook ResearchGate

Abstract. This new version of the handbook takes into account the latest developments in milling and processing activities. It incorporates the latest technologies

Palm Oil Extraction Process And Nutrients - Palm Oil Mill

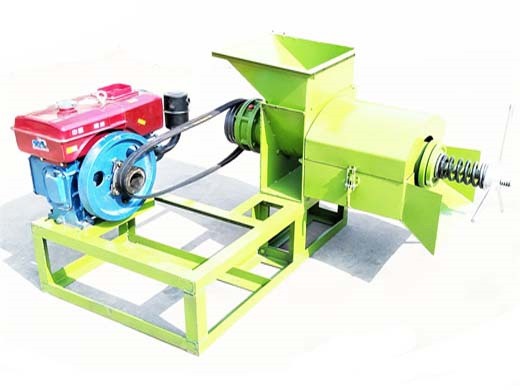

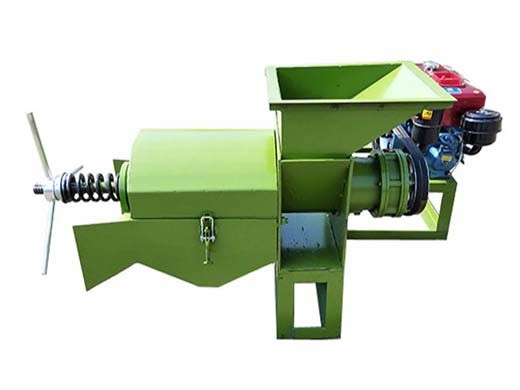

Palm oil extraction process and nutrients Extraction process Crude palm oil(CPO) and palm meal (PE) can be obtained from the pulp of palm by the process of boiling, crushing and extracting.

Single-step extraction–esterification process to produce

This investigation explores single-step biodiesel synthesis using palm oil mill effluent (POME) as a feedstock. Normally considered a waste product from the

Palm and Palm Kernel Oil Production and Processing

The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18?3% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%. The simplified palm oil extraction process is shown in Fig. 8.3. The basic quality parameters for palm products are tabulated in Table 8-B.