Life cycle assessment of extraction of edible oil from mustard

It is the oil filteration & packaging process that accounts for the majority of the overall ODP of oil extraction process (89.67 percent), followed by the seed + seed cleaning machine (7.21 percent) and oil expeller (1.77 percent). The

Life cycle assessment of extraction of edible oil from

The present study assessed the environmental hotspots of mustard oil extraction process from mustard seeds using a life cycle assessment (LCA) method. This study applies the LCA methodology to assessing environmental hotspots in the entire chain of the oil extraction and comparing the environmental impact of each process at the stages of

Life cycle assessment of extraction of edible oil from mustard

Life cycle assessment (LCA) has been used to quantify the potential environmental impact of a process. The present study assessed the environmental

Optimization and kinetic modeling of oil extraction from

White mustard seed oil (WMSO) was extracted from the ground seed by cold pressing and Soxhlet extraction using n揾exane.A two搒tep process consisting of cold pressing of white mustard seed (WMS) and extraction of WMSO from press cake (maceration) was also employed to improve the overall WMSO recovery.

White Mustard (Sinapis alba L.) Oil in Biodiesel Production

Sinapis alba L. (white or yellow mustard, also known as Brassica hirta) is an annual plant of the family Brassicaceae that originates from the Mediterranean region (Katepa-Mupondwa et al., 2005). It is found worldwide as a cultivated plant species as well as a weed. It is a winter–spring plant that can be grown in short cycles, commonly in rotation...MDPI

Mustard oil

Mustard oil can mean either the pressed oil used for cooking, or a pungent essential oil also known as volatile oil of mustard. The essential oil results from grinding mustard seed, mixing the grounds with water, and isolating the resulting volatile oil by distillation. It can also be produced by dry distillation of the seed.

Processes Free Full-Text Extraction Methods of Oils

A cocktail of cellulase, pectinase and hemicellulase was used to extract oil from yellow mustard flour through a 3-h enzyme-assisted aqueous oil extraction set

Processes | Free Full-Text | Extraction Methods of Oils

A cocktail of cellulase, pectinase and hemicellulase was used to extract oil from yellow mustard flour through a 3-h enzyme-assisted aqueous oil extraction set to pH 4.5?.0 and 40?2 C. Yields of 76% of oil and 75% of protein were reported, which were significantly higher compared to aqueous extraction leading to yields of 56% of oil

Mustard Oil: Extraction, Yield and Uses Agriculture

The yield also depends upon the machinery used for extraction. The expellers yield 34-38% oil, rotary mills 33-35% and ghanis 30-32%. The average yield of

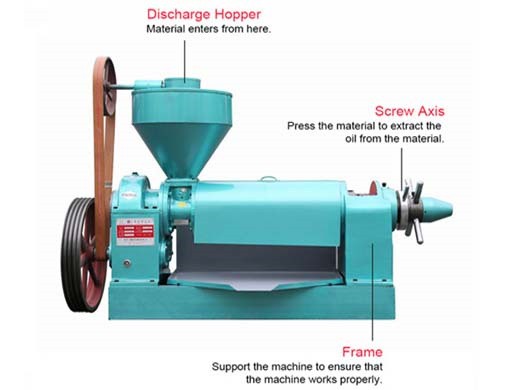

mustard oil manufacturing process - Oil Mill Machinery

The oil is made by pressing of the seeds or by the process of grinding, whereby it is mixed with water and then further distilled. The black mustard yields a lighter colored and stronger tasting oil, while the white variety produces a yellowish colored, pungent oil. A simple mustard oil recipe is to directly press the seeds.