Customer cases GEA

Customer case Largest brewery in Cyprus selects “trusted partner” GEA to configure cutting-edge, turnkey upgrade and expansion of entire beer processing line Customer

Oil, Gas and Mining Process Solutions | Dow Inc.

Oil, Gas and Mining Oil, Gas and Mining Meeting Global Energy Needs Optimize operations across the energy value chain Efficient, reliable and safe operations are critical for the energy sector to meet demand, while keeping costs low and protecting people and planet.

Palm oil processing and production process Alfa Laval

Palm oil processing. Alfa Laval has worked alongside palm oil producers since the earliest days of the industry. More than 50 years’ experience has gone into smart palm oil

Machine Customers Will Decide Who Gets Their Trillion-Dollar

Machines are logic- and rule-based. Their motivation is to solve a problem. Their assumptions will be visible in their rules and queries as well as the decisions they make. Humans often keep their intentions hidden during the buying process. Machines can檛 have a 減oker face?in the traditional sense.

GEA Crude Oil Treatment Systems

365 / 24 availability Back-up capacity with multiple separation units in operation Continuous operation with an uptime of > 98.5 %, depending on the service level agreement

Refining crude oil - the refining process - U.S. Energy

Petroleum refineries are complex and expensive industrial facilities. All refineries have three basic steps: Separation Conversion Treatment Separation Modern separation involves piping crude oil through hot furnaces. The resulting liquids and vapors are discharged into distillation units.

Palm oil milling equipment and machinery | Alfa Laval

Partnering with our customers for palm oil success 2022-02-03 Ensuring minimal downtime in high-volume palm oil processing at Kilang Sawit Bukit Bandi In the

The process of crude oil refining | EME 801: Energy Markets

The first process is known as distillation. In this process, crude oil is heated and fed into a distillation column. A schematic of the distillation column is shown in Figure 2.2. As the temperature of the crude oil in the distillation column rises, the crude oil separates itself into different components, called 渇ractions.?

Olive oil processing Alfa Laval

Case story: De Carlo For the last 50 years, the family-run olive oil producer De Carlo in Bitritto, Italy has been using Alfa Laval’s olive oil production equipment, including the

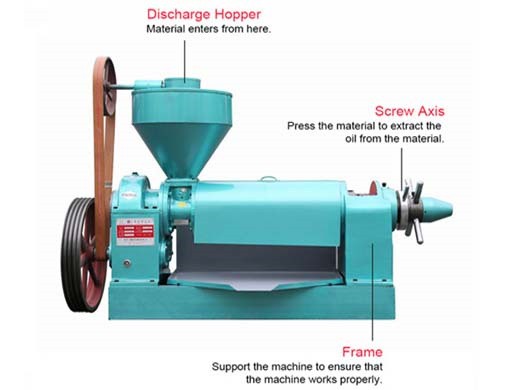

6YL-100 oil press - oil press machine

High Oil Yield Rate: compared with old and traditional oil press, the oil output rate of our oil press machine can be 5 to 8 percentage points higher. For example, use our oil press machine to process about 50 kg soybean can get about 3.5~4 kg crude soybean oil, which can greatly save cost and increase income.