Dewaxing systems Alfa Laval

Dewaxing systems. Removing wax from oils improves edible oil transparency at low temperature, which enables effective packing of the oil into transparent bottles. Alfa Laval's systems for dewaxing process separate waxes and remove impurities containing wax—safely, reliably and effectively. Comprehensive dewaxing solutions from Alfa Laval

Dewaxing systems | Alfa Laval

Alfa Laval dewaxing systems effectively remove waxes from crude oils through physical refining processes using cold enzymatic degumming or cold chemical refining processes that combine wet dewaxing, such as multi-wax and combi-wax systems, with a dry dewaxing system. Alfa Laval Cold Enzymatic Degumming system

Dewaxing Process, Oil Dewaxing Process, Sunflower Oil

Description For Dewaxing ProcessSteps For Dewaxing of Vegetable OilsTriviaSome oils are dewaxed before packing so as to remove waxes, which are dissolved in the oil. Most of the oils do not need dewaxing as they contain little or no waxes. Mainly SFO and RBO contain appreciable quantities of wax in them. This gives a hazy appearance to the oil during winter season. The reason for hazy appearance is due to the precipitati...Alibaba

Sunflower Oil Dewaxing - Five Process Alternatives - LinkedIn

1-Dewaxing with Filters This process is generally applied after crude oil degumming /neutralizing and bleaching, seeking to reduce the wax content to

Best Price Sunflower Oil Dewaxing Machine with High Efficiency

Oil residue of sunflower meal: ≤ 1.0% Moisture of meal: 12% (adjustable) Solvent residue of sunflower meal: ≤ 500PPM Total volatiles matter of crude oil: ≤ 0.2% Residual solvent of crude oil: ≤ 100PPM ---Main Consumption Index:

Dewaxing Process, Oil Dewaxing Process, Sunflower Oil

The reason for hazy appearance is due to the precipitation of dissolved waxes. The presence of wax makes the oil appear cloudy at room temperature. The oil normally becomes cloudy in 5? h but with proper dewaxing the oil remains clear after 24h of storage at 0藲C. Dewaxing is carried out by chilling the oil up to 10-15 C into the crystallizers.

Sunflower Oil Dewaxing Equipment

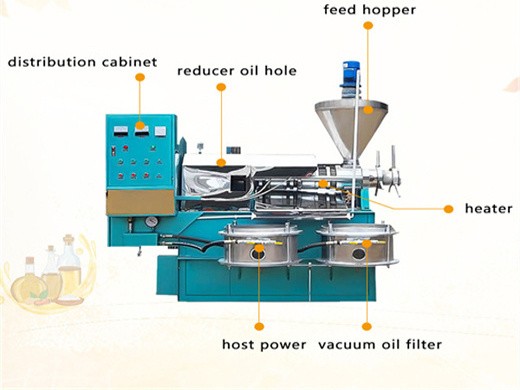

Dewaxing process. There are many methods for dewaxing oil. At present, the most commonly used is the dewaxing method, that is, freezing crystallization and separation. 1. Dewaxing process. Oil to be dewaxed → Cooling and Crystallization → Maturation → Filtration (Wax paste) → Finished oil. 2.Main equipment for dewaxing process.

Oil Dewaxing Winterization,Fractionation - Oil Mill Plant

Oil such as sunflower seed oil contains less wax which could be dewaxed by cooling to 10~15鈩?in 2 days and then pumping to the plate filter with compressed air. The dewaxing effect is good with a wax content in dewaxed oil is only ten milligrams per kilogram.

Why does sunflower oil need dewaxing?_Tech

In sunflower oil and rice bran oil, there are high content of wax, which influence the quality and flavour of refined sunflower oil, so sunflower oil need dewaxing. Sunflower oil dewaxing technology, also called winterization, is typically used in sunflower oil refinery plant. The clarity and brightness of dewaxed sunflower oil are both

Why does sunflower oil need dewaxing?_Tech

If sunflower oil is not dewaxed, the presence of wax makes the oil appear cloudy at room temperature. But after dewaxing, the sunflower oil remains clear after 24h of storage at 0藲C. Henan Doing Company can provide all kinds of sunflower oil refining machine and dewaxing machine for you.