Palm Oil Mill Effluent Treatment Processes—A Review

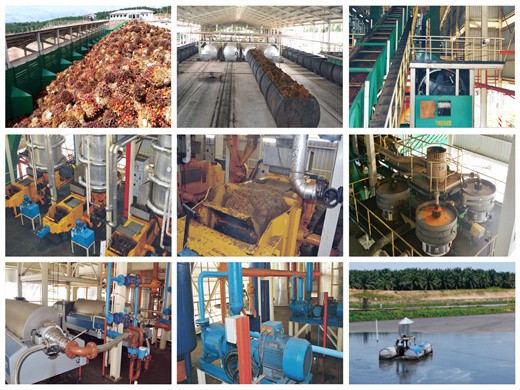

Characteristics of Palm Oil Mill Effluent (POME) Typically, in the process of oil palm, POME is accumulated from three different sources such as clarification wastewater, sterilizer condensate, and hydro-cyclone wastewater [ 22 ]. The general characteristics of each raw POME are presented in Table 1.

Palm oil milling equipment and machinery | | Alfa Laval

Modern processing for minimized water use and maximized palm oil recovery Based around our advanced, 3-phase PANX decanter, Alfa Laval D3 PRO is the industry only all-in-one processing solution that can process undiluted crude palm oil with consistent performance, even at high capacities.

Recent advances on palm oil mill effluent (POME

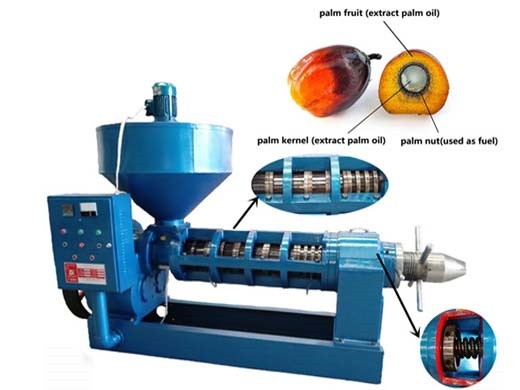

The utilisation of palm oil mill effluent (POME) as a feedstock has gained the interest of researchers to control waste production in agricultural sector derives from the palm oil industry. Palm oil plantations can be found abundantly in Southeast Asian countries, such as Indonesia, Malaysia, and Thailand, which produced approximately 36,

Palm oil processing and production process | Alfa Laval

For decades Alfa Laval has provided palm oil mills with efficient equipment to convert sterilized and pressed palm fruit into crude oil, playing a key part in shaping the design of today oil room. POME treatment To remain competitive, millers have to find the most cost effective and sustainable solution to deal with this harmful pollutant.

Palm oil processing and production process Alfa Laval

Palm oil processing. Alfa Laval has worked alongside palm oil producers since the earliest days of the industry. More than 50 years’ experience has gone into smart palm oil processing solutions for the entire supply chain milling, POME management, refining and more. Our complete range helps you increase yield while meeting increasingly

Treatment and Valorization of Palm Oil Mill Effluent through

Palm oil mill effluent (POME) is high strength wastewater derived from processing of palm fruit. It is generated in large quantities in all oil palm producing nations where it is a strong pollutant amenable to microbial degradation being rich in organic carbon, nitrogen, and minerals. Valorization and treatment of POME with seven yeast isolates was studied under scalable conditions by using

Palm Oil Mill Effluent (POME) Characteristic in High Crop

Palm oil mill effluent (POME) is a wastewater generated from palm oil milling activities which requires effective treatment before discharge into watercourses due to its highly polluting properties. The characterization of wastewater is the essential step in the design of any wastewater treatment plant (WWTP) in the industry as conducting pilot

Single-step extraction揺sterification process to produce

This investigation explores single-step biodiesel synthesis using palm oil mill effluent (POME) as a feedstock. Normally considered a waste product from the extraction process of palm oil, POME treatment is difficult and can cause significant environmental pollution if discharged directly into watercourses. Fatty acids (FAs) present in POME were extracted and subsequently esterified in situ to

Palm oil milling equipment and machinery | Alfa Laval

Based around our advanced, 3-phase PANX decanter, Alfa Laval D3 PRO is the industry’s only all-in-one processing solution that can process undiluted crude palm oil with consistent performance, even at high capacities. D3 PRO requires no dilution water, meaning a reduction in water and effluent of up to 20% and major OPEX savings from

Improving Sustainability of Palm Oil Production by Increasing

The palm oil milling process generates a considerable amount of solid-liquid effluent, which is collectively known as the palm oil mill effluent (POME). The three major sources of POME are the steriliser condensate from the steam steriliser, the sludge effluent from the oil-sludge separator and the wastewater produced from the hydrocyclone.