Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of

Palm and Palm Kernel Oil Production and Processing

The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18?3% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%. The simplified palm oil extraction process is shown in Fig. 8.3. The basic quality parameters for palm products are tabulated in Table 8-B.

5. PALM KERNEL OIL EXTRACTION Food

MechanicalextractionSolvent ExtractionTraditional Method of Palm Kernelextraction

5. PALM KERNEL OIL EXTRACTION - Food and Agriculture Organization

Palm kernel extraction is a specialised operation undertaken by a completely different set of processors. They are usually better organized as a group and are not as dispersed as palm oil processors. The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying.

Palm Kernel an overview ScienceDirect Topics

Palm kernel, the by-product of the oil palm industry, has a great potential for a source of oil and dietary protein. The extraction procedure of oil from the palm kernel is distinct from

Palm Kernel Solvent Extraction Plant - Oil Expeller

The Solvent extraction process of Palm kernel will be carried out with the following steps. Method 1: Pre-Press with Solvent Extraction Cleaning Magnetic Separation Pre-Pressing Solvent Extraction Method 2: Full Press with Solvent Extraction Cleaning Magnetic Separation First Pressing Second and Final Pressing Solvent Extraction

Mathematical Modeling of the Solvent Extraction of Palm

parts of tropical oil plant like the Elaesis guineesis (Amira et al., 2014). Palm kernel oil is extracted from kernel (or seed) that is encased in the endocarp of the palm fruit while

Palm kernel oil extraction - The malaysian experience

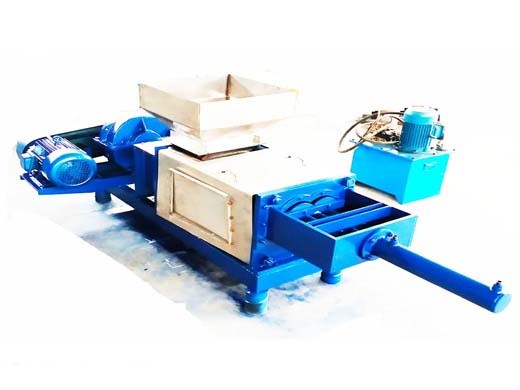

In direct screw pressing, kernels must undergo seed preparation steps of size reduction, flaking and steam conditioning prior to mechanical extraction. Mechanical wear and tear, maintenance expenses and electricity are the major costs. The direct solvent extraction process is used in larger plants.

Solvent Extraction Plant Eonmetall

Palm Kernel Oil Extraction (PKOE) Plant, is designed to extract the oil from kernel cake by means of solvent. This shall extract an additional 3% PKO. Palm Fibre, Max of 10%

Solvent Extraction Plant ?Eonmetall

Palm Kernel Oil Extraction (PKOE) Plant, is designed to extract the oil from kernel cake by means of solvent. This shall extract an additional 3% PKO. Simple, Robust, User Friendly and Flexible Our proven PFOE plant design is simple, robust, user friendly and flexible with inbuilt safety features.