Bioenergy in the Palm Oil Processing Sector in Ghana

PKS) and liquid residues known as palm oil mill effluent (POME). Ghana generates around 1 Mt of solid residues and 1.4 Mt of POME per annum. Bioenergy applications

Processing practices of small-scale palm oil producers in the

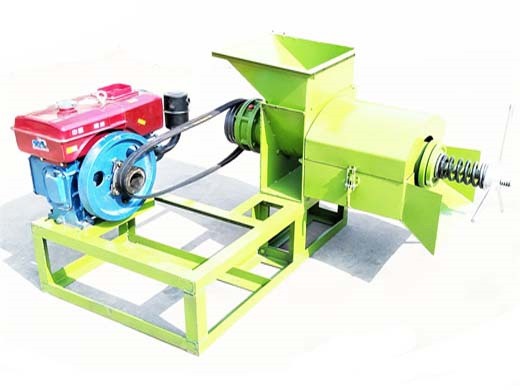

The oil palm fruits are usually processed into crude palm oil using semi-mechanized processing equipment at a milling site. The mill is locally called 楥ramer?after a Belgian engineer who first set up a small-scale mill in the district in 1982 (Nana Yeboah, 2010, personal communication).

Processing practices of small-scale palm oil producers

Ghana produces about 2,000,000 metric tons of oil palm fruits annually, and small-scale processors contribute about 60% of crude palm oil production.

Recent advances on palm oil mill effluent (POME) pretreatment

Provides a study on biogas production from palm oil mill effluent (POME) as a promising renewable energy alternative. ?Describes the implementation of recent feasible pretreatment techniques for POME to enhance biogas production. ?Evaluates the prominent bioreactors used in the anaerobic digestion of POME. ?/p>

Palm Oil Mill Effluent Treatment Processes擜 Review - MDPI

Palm oil mill effluent (POME) exists in forms of high solid, oil, and grease and includes biochemical oxygen demand (BOD) and chemical oxygen demand (COD) in richness. These are major concerns in environmental pollutant due to their adverse effects to many forms of life [ 1 ].

Small-Scale Palm Oil Production in Ghana: Practices

The environmental impact of small-scale palm oil processing mills in Ghana has come under serious questioning, especially the disposal of wastewater

Palm oil processing and production process | Alfa Laval

For decades Alfa Laval has provided palm oil mills with efficient equipment to convert sterilized and pressed palm fruit into crude oil, playing a key part in shaping the design of today oil room. POME treatment To remain competitive, millers have to find the most cost effective and sustainable solution to deal with this harmful pollutant.

Characterization of Palm Oil Mill Wastewater: The Case

The study was conducted in the Central Region of Ghana. The current population of the region is estimated at 2,563,228 inhabitants (Citypopulation 2019). Based on climate, the region is divided into three agro-ecological zones namely coastal savanna, transitional and forest zones (MOFA 2020). The average temperature ranges between 24 °C and 34 °C w...MDPI

Palm oil milling equipment and machinery | | Alfa Laval

Modern processing for minimized water use and maximized palm oil recovery Based around our advanced, 3-phase PANX decanter, Alfa Laval D3 PRO is the industry only all-in-one processing solution that can process undiluted crude palm oil with consistent performance, even at high capacities.

Palm Oil Mill Effluent Treatment Processes—A Review

Characteristics of Palm Oil Mill Effluent (POME) Typically, in the process of oil palm, POME is accumulated from three different sources such as clarification

Oil Palm Processing in Ghana: Hanging In, Stepping Up and Stepping Out

In terms of stepping out of oil palm production, there is an emerging trend of farm households of all types cutting their palm oil trees to plant rubber and or cocoa. The farmers are motivated by the fact that rubber and cocoa are more lucrative than oil palm. Additionally, for cocoa especially, the state supports farmers from production to