Investigation on walnut kernel oil extraction using different methods

The optimal extraction conditions of walnut oil by Soxhlet were solid to liquid ratio of 1:7, temperature of 76 °C, time of 4 h, and the extraction efficiency of walnut oil was 58.3%.

Examining the Walnut Oil Market from 2023 to 2030

The MarketWatch News Department was not involved in the creation of this content. Apr 11, 2023 (The Expresswire) -- Walnut Oil Market Size 2023-2030 | New Report (134 Pages) | In This Reports

Full article: Phenolic extracts from colored-walnut pellicles

Lecithin (Sigma-Aldrich) was used as an emulsifier for the phenolic enrichment of walnut oil [25 Briefly, 0.3% of lecithin (w/v) was dissolved in walnut oil, and then a solution of

Investigation on walnut kernel oil extraction using different

The optimal extraction conditions of walnut oil by Soxhlet were solid to liquid ratio of 1:7, temperature of 76 C, time of 4 h, and the extraction efficiency of walnut oil was 58.3%. The extraction efficiency of pressing was 43.2%. Walnut oil mainly contains phosphorus, zinc, magnesium, potassium, calcium, and other elements.

An Overview on Traditional vs. Green Technology

Gonzalez-Gomez et al. investigated the best settings for enzyme-assisted extraction to produce superior walnut oil and also reported the optimal conditions for walnut oil extraction (pH 4.0,

Salt-assisted aqueous extraction combined with Span 20 allow

The new aqueous extraction processing (AEP) procedure that was finally developed in this study recovered 91.2% walnut oil with high quality. Span 20 is effective in destabilizing the emulsions and improving oil recovery, which may be due to the fact that Span 20 could effectively replace the position of the oleosin to destabilize the emulsion.

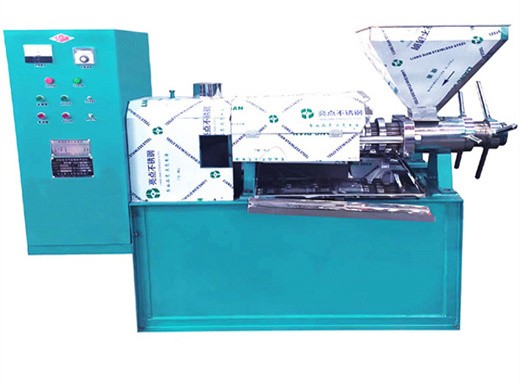

Walnut Oil Extraction Process, Machines and Plant Low

160L Walnut Oil Processing Unit. Oilcake Size: volume < 0.5cm3. Extraction Times: 4 times. Extraction Temperature: 25 ~ 35℃. Material Solubility Ratio: 1∶1.2 ~ 1∶1.25.

An Overview on Traditional vs. Green Technology of Extraction

Walnut oil can be extracted using traditional as well as new and green technologies. The chosen extraction method has a significant impact on the lipids and other important components extracted. It is critical to select a suitable extraction process for the compounds of interest.

(PDF) Optimization of walnut oil production ResearchGate

Content of tocopherols in walnut oil obtained by pressing and oil extracted by supercritical CO 2 were compared. Experimental set

The Supercritical carbon dioxide extraction of 蠅-3, 蠅-6

A central composite design approach was used to optimize the supercritical carbon dioxide (SCCO 2) extraction of Italian Walnut oil, considering the effect of pressure (from 82.3 to 317.6 bar), temperature (from 309.7 to 326.5 K) and process time (from 1.5 to 6.5 h) on extraction yield, fatty acid composition and 尾-sitosterol content.