Olive oil decanter centrifuge for industrial-scale olive oil mills

The new Alfa Laval Sigma 8 two-phase olive oil decanter centrifuge takes industrial-scale extraction of olive oil to a new level. Sigma 8 combines outstanding yield and operating

Centrifuge - 3-Phase Separating Decanters for Oil Recovery

3-Phase decanters separate both, the olive pulp or the palm oil sludge into oil, water and solids. This 3-Phase separation requires a comparably high amount of dilution water. In olive oil production GEA also offers 3-Phase decanters for treating the waste water from the olive oil recovery process.

Separators for Oil Recovery GEA

The big advantage of the 2-phase separating decanter for olive and palm oil recovery is the enormous savings when it comes to dilution water. 3-Phase Separating Decanters for

Oil Centrifuge | Working, Benefits, Size, Types, Examples, Cost

An oil centrifuge works on the principle of differential settling using a high centrifugal force to separate oil from solid and liquid contaminants. The centrifuge exerts up to 10,000 Gs of force to separate particles as small as 1 micron from the oil. It also separates any immiscible liquid contaminants from the oil. Benefits (Advantages)

Use of centrifuge how separation works Alfa Laval

Separation technologies are essential to a broad range of industries—from food, beverage and pharma to marine and energy through to water and waste treatment. Various

Industrial Centrifuge Systems | Trucent

Trucent CentraSep DX Series centrifuge machines offer both two-phase and three-phase processing. (淭wo-phase?is liquid-liquid separation, usually separating water-based and oil-based liquids or a liquid from a solid; 渢hree-phase?refers to liquid-liquid-solid separation, which separates a water phase, oil phase, and solids.)

Oil Centrifuging Machine Vegetable Oil Centrifuge Latest

Ask Price. Mariya Engineering Works. Contact Supplier. KTEC Oil Recovery Chip Centrifuge Machine/ Chip Wringer, Capacity: 60 kg per hour. ₹ 3.51 Lakh. Fintek Engineers.

Industrial Centrifuge for Liquid Base Applications

An advanced version of the traditional separators used for liquid-based applications, our versatile centrifugal separator is able to process flow rates of up to 100,000 litres per hour, efficiently separating soft and fibrous oversized solids from liquid slurry.

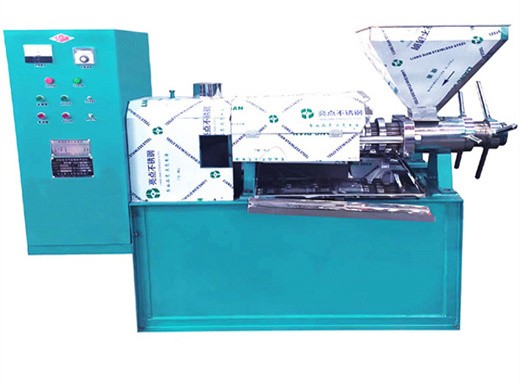

big oil separating centrifugal machine big scale oil refining

big oil separating centrifugal machine big scale oil refining machine coconut oil refining machine can press different oilseeds, such as sesame, peanut, soybean, sunflower

Centrifuges & Separation Equipment

Centrifuges & Separation Equipment Since 1893, GEA has been building centrifuges which combine high separating efficiencies, clarifying efficiencies and throughput capacities with maximum savings in terms of energy, water and disposal costs. Contact us Get a quote Centrifuges & Separation Equipment Overview Products Service products Customer cases