Palm and Palm Kernel Oil Production and Processing

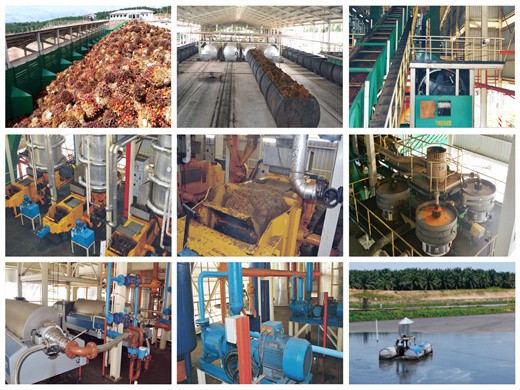

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding

5. PALM KERNEL OIL EXTRACTION - Food and Agriculture Organization

The floating kernels are scooped in baskets, washed with clean water and dried. Periodically, the shells are scooped out of the bath and discarded. The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder.

How the palm oil industry is transitioning to net-zero

Although palm oil has its positives, it is frequently associated with deforestation and significant greenhouse gas emissions. To address these concerns, the

Palm and Palm Kernel Oil Production and Processing

The whole oil palm value chain covers the growing and production of FFB in plantations, extracting CPO and palm kernel and PKO in palm oil mills and kernel crushing plants, and producing various types of refined palm and palm kernel oil products and blends for edible and non-edible applications.

5. PALM KERNEL OIL EXTRACTION Food and Agriculture

MechanicalextractionSolvent ExtractionTraditional Method of Palm Kernelextractionpalmoilmillplant

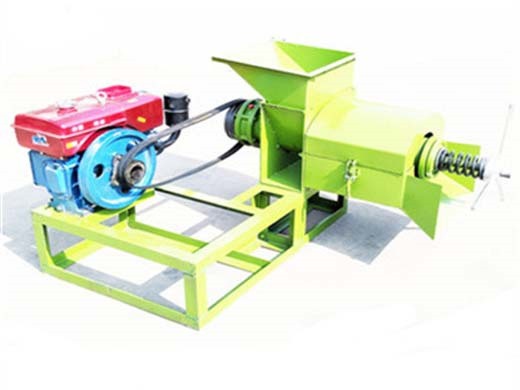

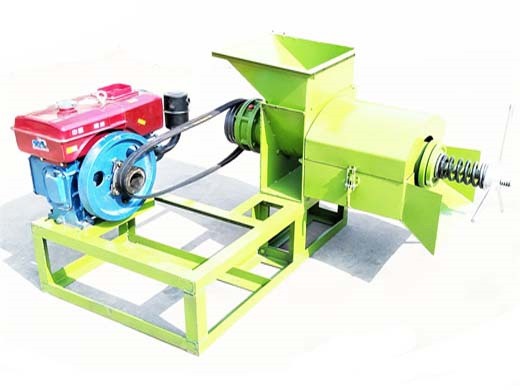

Palm Kernel Oil Production Line Cost and Equipment

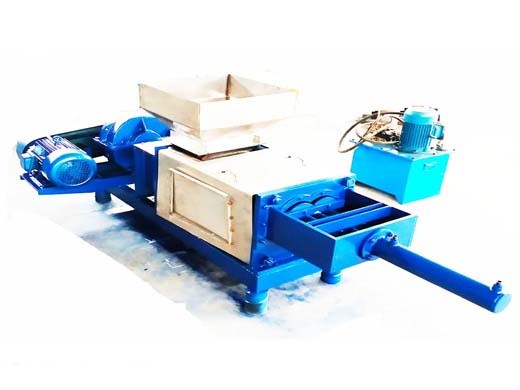

The production process of palm kernel oil: Separation of Kernel and Shell 鈫?Crushing 鈫?Steaming 鈫?Pressing 鈫?Oil Clarification 鈫?Crude Palm Kernel Oil. Below is the detailed process of palm kernel oil production. (Latest Post: Palm Oil Processing Plant Cost >>) Small Palm Kernel Oil Production Line Kernel Shell Separation

Palm Kernel Oil Production Line Cost and Equipment

When facing the various model of palm oil processing equipment, many customers will lost and have no idea about how to choose suitable equipment for palm kernel oil

Setup a Profitable Palm Kernel Oil Processing Plant ?Design

This two equipment are specially designed for palm kernel and it can greatly improve the efficiency of palm kernel cracking and as well as the quality of final produced palm kernel oil. Please note that fresh palm kernels contain 20% moisture. For better storage, it is better to reduce its moisture less than 7%. Palm Kernel Crusher.

[Beginners Guide] How To Process Palm Kernel Oil Agrolearner

The resulting oil-solvent mixture is then separated, and the solvent is evaporated to leave behind the oil. The steps include: Step 1. Extraction. The crushed

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum

Palm Nut is one of the byproduct of Palm Oil Extraction Plants. These Nuts comprise of about 50% Palm Kernel. Proper Separation Technique is necessary to recover the kernels from these nuts. Ripple Mills are used to crack the Palm nuts.