Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding period. In the case of Indonesia, the industry has grown rapidly with the oil palm

(PDF) Properties, machines and processes for industrial

A study was conducted to investigate the relationship between temperature (20 oC to 100 oC) on the dynamic viscosities and densities of refined Palm Kernel Oil, unrefined Palm Kernel Oil, soybean

3. PALM OIL PROCESSING Food and Agriculture Organization

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms.

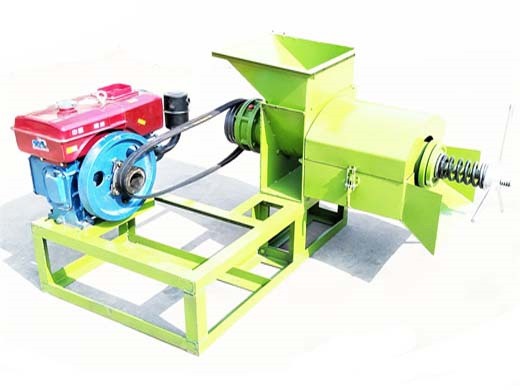

Palm Kernel Oil Expeller for Cold Pressing of Palm Kernel Oil

The palm kernel oil expeller machine is also added with the seed frying and automatic heating function which changes the traditional heating method of cake grinding press, so as to shorten the preparatory work time, reduce the energy consumption & the abrasion of the machine and prolong the service time of expeller.

Design and Fabrication of a Palm Kernel Oil Expeller

Worm Screws in palm kernel oil screw press have been found to fail often and usually require constant replacement. The failure rate is also more with locally fabricated worm screws which usually

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum

PALM KERNEL OIL PROCESSING PROCESS Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit Palm kernel Mechanical Pressing Unit Palm Nut Cracking & Shell Separation Unit Palm Nut is one of the byproduct of Palm Oil Extraction Plants.

5. PALM KERNEL OIL EXTRACTION Food

MechanicalextractionSolvent ExtractionTraditional Method of Palm KernelextractionMechanical extraction processes are suitable for both small-and large- capacity operations. The three basic steps in these processes are (a)kernel pre-treatment, (b) screw-pressing, and (c) oil clarification. Diagram 2: Mechanical extractionof palm kernel oil. Line (A) is for direct screw-pressing without kernelpre-treatment

3. PALM OIL PROCESSING - Food and Agriculture Organization

The stages in this process comprise grinding the kernels into small particles, heating (cooking), and extracting the oil using an oilseed expeller or petroleum-derived solvent. The oil then requires clarification in a filter press or by sedimentation.

The Development of Expeller for Palm Kernel based Seed

The screw (expeller) press is extensively used for commercial extraction of palm kernel oil (PKO) from oil-palm kernels. In this work, Magnus (Nig.)screw press (Model MS-100,) locally fabricated

ANNEX 1: Major manufacturers and designers of palm processing

The nutcracker, kernel/shell separator and palm kernel expeller are produced to handle palm kernel. The expeller has machined flights on a single shaft with threaded backpressure cone. Generally machines are produced having a 1 tonne/hr capacity for palm oil while the palm kernel machines have rated throughputs of 150-250 kg/hr.