Efficient and eco-friendly extraction of corn germ oil

An improved aqueous extraction method has been established for extraction of oil from corn germs. This method primarily included steam explosion

Efficient and eco-friendly extraction of corn germ oil using

Introduction. Corn germ is a substantial byproduct of the wet milling and alcohol industry of corn. Corn germ (dry) contains 35?6 % oil, with linoleic acid (C18:2) being the predominant fatty acid (49?1.9 %) and the highest level of tocopherol and phytosterol amongst all vegetable oils, which is a cost-effective resource for healthy nutritious oil.

Efficient and eco-friendly extraction of corn germ oil using

A process for the aqueous enzymatic extraction of corn oil from dry milled corn germ and enzymatic wet milled corn germ (E-Germ) J Am Oil Chem Soc. 2009; 86:469–474. doi:

Bioactive Phytochemicals from Corn (Zea mays) Germ Oil

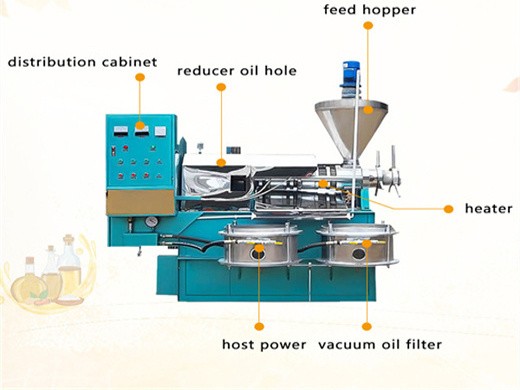

According to the same authors, several methods are used for the recovery of corn germ oil, such as pressing, solvent, extraction of aqueous, enzymatic, and supercritical fluid. Corn oil production reached 1.5 million tons, mainly because it became an essential type of edible oil in China [ 48 ].

Oil and protein recovery from corn germ: Extraction

View Open Manuscript Other access options Food and Bioproducts Processing Volume 120, March 2020, Pages 131-142 Oil and protein recovery from corn

Corn Germ - an overview | ScienceDirect Topics

Corn germ oil is a by-product of the corn oil milling process. Most corn that is harvested is used as feed but the proportion of the corn that is milled is increasing because of bioethanol production. During the wet milling process, the germ is isolated from the starch using cyclone separators, washed, and dried.

Corn Germ an overview ScienceDirect Topics

Besides cornstarch and corn oil as the main products of wet milling process, the process generates multiple coproducts of corn gluten feed, corn gluten meal, corn germ meal,

Oil and protein recovery from corn germ: Extraction yield

This work aimed the recovery of oil and protein fractions from corn germ (CG) generated as a by-product during flour processing. Several oil extraction techniques were investigated: hexane at room temperature, hexane at 45 C, supercritical carbon dioxide (Sc-CO 2) and Soxhlet with hexane and ethanol.

Process for recovery of corn oil from corn germ

After being rehydrated, the corn germ is conditioned, or heat treated, for a short time at a temperature of 160-180° F., preferably 175-180° F., for 15-30 minutes, preferably 30

Coprocessing Corn Germ Meal for Oil Recovery and Ethanol

Due to the insufficient availability of engineered oil-bearing crop samples, corn germ meal, with 2.3% oil on a dry basis , was used as a model lignocellulosic energy crop. Corn germ meal, the solid residue of corn germ after oil extraction from wet-milled corn, is a low-value product rationed in ruminant animal diets [ 21 , 22 ].