Peanut Oil Processing Technology ScienceDirect

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the

ANS 312 -- Applied Animal Nutrition Feedstuffs and Ration

The majority of cottonseed is either processed using the direct solvent method or the prepress solvent method. For monogastrics, processing via direct solvent or prepress solvent is recommended. For monogastrics, cottonseed meal may be fed at less than 25% of the total protein supplement. Cottonseed meal is a more suitable feedstuff for ruminants.

Processing and Food Uses of Peanut Oil and Protein

A ton of shelled peanuts increased oil yield to 100–115 gallons and 1100–1200 pounds of cake at 40–50% protein. Data ( Dean and Sanders, 2009) on the

Processing and Food Uses of Peanut Oil and Protein

Only four crushing plants in the US process peanuts into oil/protein with expeller pressing the technology of choice. Just one plant uses expellers followed by hexane extraction. Peanuts are a relatively high-oil oilseed (with about 50% oil) and the meal after expelling contains about 6?% oil.

(PDF) Cottonseeds and Crude Peanuts Oils Production

The cottonseed oil showed 88.58 ± 11.86 g of iodine / 100 g. This average is below the codex alimentarius standard value, Sterols were detected in all

Find the Right Big Scale Oil Expeller at Oil Mill Plant!

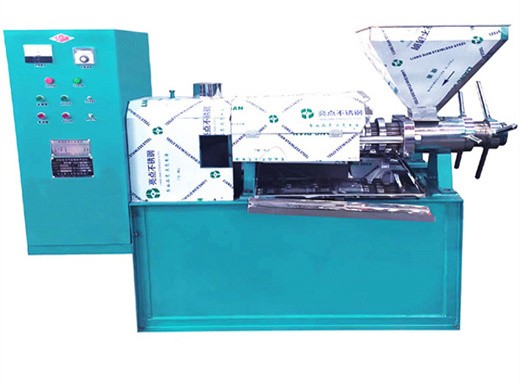

202-3 Oil Expeller. The Model 202 screw prepress is a continuous oil expeller to process oil rich seeds (such as peanut kernels, cottonseed kernels, rapeseeds and sunflower kernels), used for pre-pressing extraction or twice pressing. The cakes are loose but not crushed so that the solvent can penetrate easily.

Peanut oil press and peanut oil pressing technology

1. Shelling and kernel shell separationRequirement for shelling: no shell in the kernel (or shell content is less than 2-4%), kernel content in shell is lower than 0.5%. Shelling equipment: currently, knife cage shelling and kernel shell separation equipment are used.Softening, flaking and cookingPeanut kernel has soft texture, generally do not need to soften. Sometimes, it can be flaked only after proper heat treatment (adjusting moisture). The flake thickness should be less than 0.5mm when being used for hot pressing. Prevent sticking of roller in flaking process. Generally, cookinseedoilpress

Large Scale Prepress Screw Oil Mill - Peanut Oil Press

Prepress expeller is a continuous screw expeller, which is applicable for prepress-extraction process or twice press process of vegetable oil plant, can be used to press oil-bearing crops such as peanut kernel, cottonseed kernel, rapeseed and sunflower Large Scale Prepress Screw Oil Mill

Peanut Oil Press-- Integrated Screw Oil Press for Both

1. A wide range of application. It can press more than 20 kinds of oil plant seeds, such as soybean, peanut, sesame, rapeseed, sunflower, olive, palm, coconut

Oil Expeller - Palm Oil Mill Machine Leading Manufacturers

Big YZY340 Oil Prepress Expeller. YZY340 screw press is a new big pre-press which has high rotating speed, thin cake and can get oil both from outside and inside, specially suitable for the pre-pressing and solvent extraction or twice pressing process, it can be used for the pressing of peanut kernel, cottonseed kernel, rapeseed and sunflower seed kernel, etc. Features