A Comprehensive Review on 1st-Generation Biodiesel

The rapid depletion of conventional fuel reserves and the increase in environmental pollution prompted the search for a sustainable energy solution. Biodiesel

Biodiesel production from palm olein: A sustainable

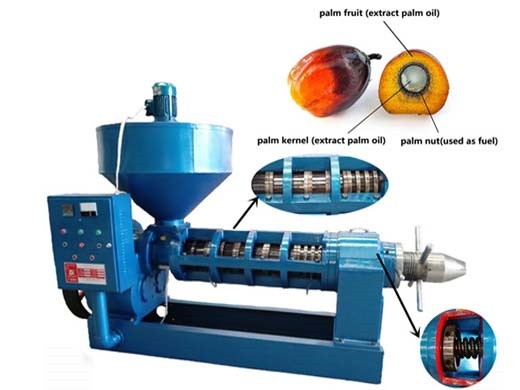

Direct comparative analysis has shown that the Nigerian oil palm industry has the prospect of producing biofuels commercially (Ishola et al., 2013 ). Worldwide, palm trees account for around 10% of biodiesel production and are proliferating rapidly (Szulczyk and Khan, 2018).

Biodiesel production from palm olein: A sustainable

This research ascertained the feasibility of producing biodiesel from a Nigerian sourced palm olein with the use of batch reactors. The percentage yield of

Production of Biodiesel Using Palm Oil - ScienceDirect

The production of all these diversified by-products simultaneously with palm biodiesel certainly enhances the economic viability of using palm oil as feedstock for biodiesel production. Specifically, the relatively higher prices of biodiesel compared to petroleum diesel may be offset by the revenue obtained from selling those phytonutrients by

Production of Biodiesel Using Palm Oil ScienceDirect

As shown in Fig. 23.3, gradual increase in the production of palm biodiesel could be seen for the past 7 years. Thus, Malaysia is projected to increase the

The advances and limitations in biodiesel production

It was reported that after the addition of ZrO 2 with sulfuric acid H 2 SO 4 the yield of biodiesel from palm and coconut oil increased from 64.5% and 49.3% to 90.3% and 86.3%, respectively (Citation 156). The reason for increasing the volume of produced biodiesel is the modification of metal oxides surface acidity.

Waste Cooking (Palm) Oil as an Economical Source

FT-IR Spectral AnalysisCharacteristics FT-IR spectral analysis of WCO and synthesized BD have been shown in Fig. 2. The FT-IR spectra of WCO and BD were found to be identical with similar chemical functionality. The carbonyl (−C=O) functionality was observed between the region 1800 cm−1 and 1700 cm−1H NMR Spectral AnalysisThe used palm oil and prepared biodiesel were investigated with 1H NMR spectra (the 1H NMR spectra was given in Supplementary materials, Fig. S1). The terminal methyl (−CH3) and methylene protons (−CH2) were observed at the peak position 0.87 and 1.25 ppm as a multiple

An overview to process design, simulation and sustainability

A wide range of feedstock (edible, in-edible oil crops and waste oils, as well as microalgae), diverse reaction and separation conditions, and different types of catalyst make biodiesel manufacturing a complex system, which not only requires empirical work, but also the modelling research efforts.

Biodiesel Production from Palm Oil, Its By-Products, and Mill

The sustainability of petroleum-based fuel supply has gained broad attention from the global community due to the increase of usage in various sectors, depletion of petroleum

Palm Oil Biodiesel

Palm oil biodiesel is nontoxic and biodegradable in addition to emitting far fewer carbon emissions than traditional petro-diesel. In addition to palm oil biodiesel, oil palm tree biomass can be turned into methane, bio-plastics, organic acids, bio-compost, active carbon, plywood, and animal feedstock. [1]