Comparison of solvents for extraction of walnut oils: Lipid yield

Walnut oils were obtained using five different extraction solvents (n-hexane, ethyl acetate, petroleum ether, Folch solution (chloroform/methanol, v: v = 2: 1) and acetone), and their lipid yield, lipid composition, minor components (tocopherols,

Comparison of solvents for extraction of walnut oils: Lipid

The squalene contents obtained in our walnut oils ranged from 5.1 to 7.7 mg/kg, with the extraction methods ranked in the order: ethyl acetate > Folch > petroleum ether > acetone > n- hexane > cold pressing, as shown in Table 2.

(PDF) An Overview on Traditional vs. Green Technology

extraction of walnut oil by demonstrating the benefits and drawbacks of different methods Agronomy 2022,12,2258 3 of 17 used in this extraction, with a

Evaluation of physicochemical properties and antioxidant

A part of sample was extracted based on an MBD method as described previously by Crowe et al. (2002). 50 g of walnut kernel was first ground into a fine powder and suspended in a mixture of 180 ml water, 200 ml methanol and 100 ml chloroform and homogenized using a laboratory polytron (model PT-1200C, Switzerland) at 5000 rpm for 2 min.

(PDF) Effects of processing methods on the chemical

Effects of processing methods on the chemical composition and antioxidant capacity of walnut (Juglans regia L.) oil August 2020 Lebensmittel-Wissenschaft und

(PDF) Effects of processing methods on the chemical

Various methods for the processing of walnut oil (cold pressing, ... Comparison of solvents for extraction of . walnut oils: Lipid yield, lipid compositions, minor-component content, and .

Comparison of solvents for extraction of walnut oils: Lipid yield

In another study realized by Gao et al. (2019b) it was shown that by using the cold pressing process, the LA content of walnut oil (67.05%) was significantly higher

Full article: Differences in Oils from Nuts Extracted

When comparing the two extraction systems, the oils of all samples (almond, pistachio, and walnut) extracted with screw press showed higher peroxide values than the oils extracted with the hydraulic press, except walnut oils. In contrast, K 232 and K 270 values were similar, regardless of the pressure system used.

Effects of processing methods on the chemical

The free radical scavenging capacity of the different oils was assessed by DPPH, FRAP, ABTS, and ORAC assays. Table 2 shows that the polar extract of HE oil

Comparison of Different Processing Methods of Iron Walnut

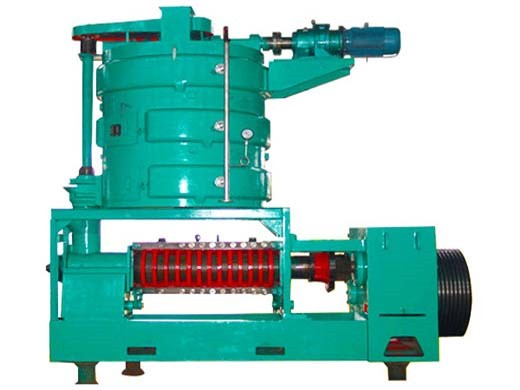

The new iron walnut oil processing method is beneficial to the development of iron walnut oil. The authors show that lipid composition of tested oils is relatively stable, while their minor components contents are significantly different. Oil antioxidant capacity is mainly related to polyphenols. Roasting-pressing can obviously improve the