Malaysia Palm Kernel Expeller Mills Manufacturer

Muar Ban Lee Group is a world-leading palm kernel expeller manufacturer specializing in palm oil machinery and oil seed crushing machinery. We provide "One Stop Service" in setting up Palm Kernel Crushing Plants from Plant Design and Fabrication to Installation and Commissionning. With

Prospects of Palm Fruit Extraction Technology: Palm Oil

MPOB ?Malaysian Palm Oil Board. OER ?Oil extraction rate. PFF ?Palm press fiber. PKO ?Palm kernel oil. POME ?Palm oil mill effluent. PORAM ?Palm Oil Refiners Association of Malaysia. PPKO ?Processed palm kernel oil. PPO ?Processed palm oil. RBDPO ?Refined, bleached, deodorized palm oil. SC-CO 2 ?Supercritical

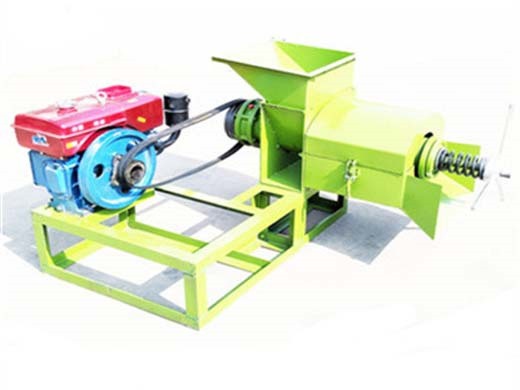

Palm Kernel Oil Expeller Machines Malaysia MBL

The palm expeller machines are used in a variety of processes to produce the palm kernel cake. These include kernel pre-treatment, grinding, flaking, steam conditioning,

Improving Sustainability of Palm Oil Production by Increasing

One strategy is to improve the oil extraction rate (OER) during the milling process. The average OER in Malaysia has remained stagnant between 19 and 21% for the past 40 years. Based on the world production of palm oil in 2018, approximately 3 million tonnes of additional palm oil can be produced globally with a 1% increase in OER.

Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of

Palm and Palm Kernel Oil Production and Processing

The whole oil palm value chain covers the growing and production of FFB in plantations, extracting CPO and palm kernel and PKO in palm oil mills and kernel crushing plants, and producing various types of refined palm and palm kernel oil products and blends for edible and non-edible applications.

Palm kernel oil extraction The malaysian experience

Strict quality control right from fruit processing to kernel extraction is necessary to ensure production of good quality oil and by-products. Malaysian palm kernel oil has proven to

Palm kernel oil extraction - The malaysian experience

In direct screw pressing, kernels must undergo seed preparation steps of size reduction, flaking and steam conditioning prior to mechanical extraction. Mechanical wear and tear, maintenance expenses and electricity are the major costs. The direct solvent extraction process is used in larger plants.

Highly Efficient Palm Kernel Oil (PKO) Processing Machines

The full set of Palm Kernel Oil (PKO) Processing Machines include Husker, Crusher, Cooker, Oil Press Expeller, Oil Filter, Oil Refinery Machine, etc.. Oil Capacity: 1~1000

(PDF) THE DESIGN AND FABRICATION OF A BATCH PALM KERNEL

The digested or mash of oil palm was pressed using screw press. The crude oil obtained was 1.22kg is further fractionated to separate oil from non-oil. The efficiency of the design was estimated