Microemulsion-based palm kernel oil extraction using

Abstract. This study introduces a novel technique using surfactant microemulsion-based oil seed extraction. To achieve this objective, microemulsion

Simulation of an Extractor for the Extraction of Vegetable Oil from

Finally is the extraction section where the oil is extracted from its source such as palm kernel with the help of a solvent to form a homogenous liquid with the oil [12]. Thus, this research study developed models that predicts the amount of oil extracted from its raw material (palm kernel) in an extractor by performing

Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of

Improving Sustainability of Palm Oil Production by Increasing Oil

Palm oil is the world most-produced vegetable oil that is serving as an important source of food and energy for many developing and underdeveloped countries. The global demand for palm oil will continue to rise, owing to the growing population and economy. Presently, tremendous efforts have been devoted to improving the sustainability of palm oil production. One strategy is to improve the

Solvent Extraction Plant Eonmetall

Palm Fibre Oil Extraction Plant, a plant designed and equipped to extract the residual oil from palm-pressed fibre by means of solvent. A food grade solvent known as hexane is

Palm and Palm Kernel Oil Production and Processing in Malaysia

The high price of palm oil and more efficient solvent recovery technology has enabled the introduction of oil recovery from the pressed palm fiber using solvent extraction. The pressed palm fiber is transported into the palm fiber solvent extraction plant for the oil recovery.

5. PALM KERNEL OIL EXTRACTION Food and Agriculture

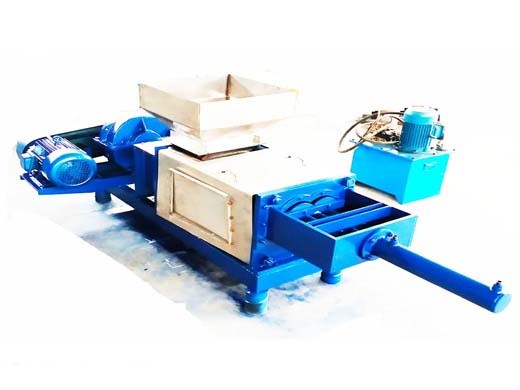

MechanicalextractionSolvent ExtractionTraditional Method of Palm KernelextractionMechanical extraction processes are suitable for both small-and large- capacity operations. The three basic steps in these processes are (a)kernel pre-treatment, (b) screw-pressing, and (c) oil clarification. Diagram 2: Mechanical extractionof palm kernel oil. Line (A) is for direct screw-pressing without kernelpre-treatmentResearchGate[PDF]

Solvent Extraction Plant ?Eonmetall

A food grade solvent known as hexane is used to extract the remaining 5% ?6% of residual crude palm oil (CPO) available in palm-pressed fibre, thereby enhancing oil extraction rate (OER) by 0.5%. Palm Kernel Oil Extraction (PKOE) Plant, is designed to extract the oil from kernel cake by means of solvent. This shall extract an additional 3% PKO.

Palm Kernel Oil Extraction Green Solvent Improving

intensied palm kernel extraction using green solvent. The oil yield using the Soxhlet oil method was 39.53 ± 2.2% with acid value of 1.06 ± 0.2%. This result is in agreement with

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at Factory Price

For large scale palm kernel oil production, there are two oil processing method, one is mechanical pressing, the other is solvent extraction. Mechanical pressing mainly adopts large scale oil press to squeeze oil, while solvent extraction utilizes solvents, such as hexane, to extract oil.