Supercritical extraction of oil seed rape: Energetic

The aim of this work is to evaluate the supercritical CO 2 extraction of rape seed oil and its energy consumption at two different scales. The influence of pressure (25–55 MPa), temperature (35–75 °C) and flow rate on the extraction yield and energy

3. PALM OIL PROCESSING - Food and Agriculture Organization

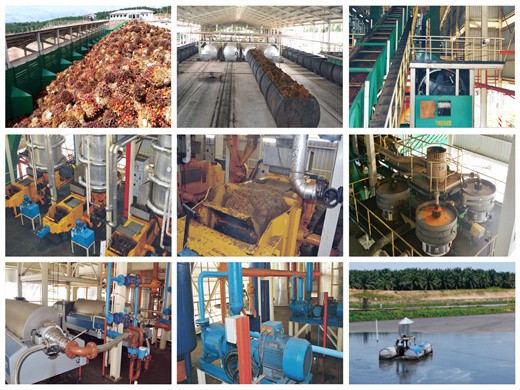

The extraction of palm oil from boiled palm fruit can be accomplished by handling successive batches of materials or continuously feeding material to the machines. 3.2.1 Batch systems. The batch systems work directly on successive loads of boiled fruit to extract oil in one operation for clarification.

Significance of Oil Extraction Rate (OER) Efficiency in a Palm

Palm Oil Engineering Bulletin No.105 (Oct Dec 2012) p35-38 Significance of Oil Extraction Rate (OER) Efficiency in a Palm Oil Mill N Ravi Menon

Improving Sustainability of Palm Oil Production by Increasing Oil

One strategy is to improve the oil extraction rate (OER) during the milling process. The average OER in Malaysia has remained stagnant between 19 and 21% for the past 40 years. Based on the...

Classification of oil palm fresh fruit maturity based on

The oil extracted from the oil palm (Elaeis guineensis) contributes to approximately 1/3 of the world’s vegetable oil, followed by oil extracted from soybean

Evaluation of alternative solvents for improvement of oil extraction

The conventional process utilizes only mechanical extraction (pre-press yields about 60% of oil) or solvent extraction, or even combines both of them [1].In order to become edible, the crude vegetable oil, a mixture of pressed and extracted oil, must undergo further refining processes for elimination of impurities and contaminants, in order to guarantee physicochemical and organoleptic

Effect of Different Extraction Methods on Quality

3.2. Sensory Quality. The sensory quality of rapeseed and flaxseed oils prepared by different oil extraction methods was evaluated based on various indicators

Solvent Extraction - AOCS

In Figure 2, it is worth noting that a plant to process rapeseed with pre-pressing followed by extraction will often reduce the oil content from about 40% to 20% in the presses and from 20% to 0.8% in extraction, and that (after adjustments for moisture changes during the process) the press oil produced may be roughly 25.8% of the raw seed, while the extraction oil may be about 13.7% of the

Extraction of palm fatty acids from sterilized oil palm

The initial extraction rate (h), the extraction capacity (y S), and the second-order extraction rate constant 30 min, and 80 g, respectively. During

Fundamental understanding of - ScienceDirect

The conventional method to produce biodiesel involves two important steps, which are lipid extraction and transesterification reaction that has been widely practiced in industry, especially for biodiesel derived from palm, rapeseed, soybean and jatropha oil [18], [19].