Elemental Composition of Palm Kernel Expeller Used as

Palm kernel expeller (PKE) is a biowaste by-product of palm oil processing in Southeast Asia that is exported as stock fodder. Global production of PKE

Elemental Composition of Palm Kernel Expeller Used as ... - MDPI

Palm kernel expeller (PKE) is a biowaste by-product of palm oil processing in Southeast Asia that is exported as stock fodder. Global production of PKE totals 11M t yr−1, of which New Zealand imports 1.9M t yr−1, worth >USD 325M, most of which supports NZ’s dairy herd of 5.5M cows. We aimed to determine the concentrations of the chemical elements in PKE imported into New

3ton/Hour Palm Kernel Oil Expeller, Palm Oil Processing Plant

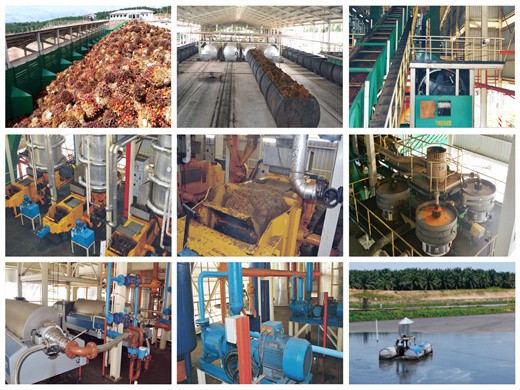

6. Clarification: Separation of major impurities (such as silt, fiber, etc.) in the oil by means of natural sedimentation 7. Vacuum dehydration equipment: As the

An overview of palm oil and palm kernel oil production process

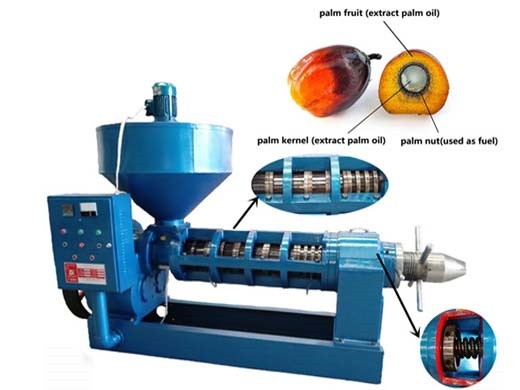

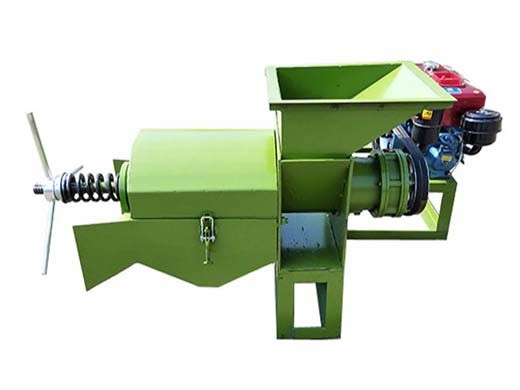

During palm kernel oil extraction process, there are 3 types palm kernel oil extraciton machine can be choosed, they are: (1)500-800kg/h palm kernel oil expeller machine (2)0.5-2tph palm kernel oil production machine. Small scale palm kernel oil production machine (3)10-1000tpd palm kernel oil processing plant. After palm kernel oil extraction

Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of

Tropical Oils - Wilmar International

Palm kernel and copra expeller are by-products of the crushing and expelling of oil from palm kernel and copra (dried coconut meat). They contain a high level of protein and are a good source of energy and nutrition, making them ideal supplements in animal feed for pigs, poultry and ruminant livestock such as dairy cow and beef cow.

An overview of palm oil and palm kernel oil production process

The whole palm oil production process consists of palm oil extraction & refining & fractionation process. Through palm oil extraction process, we can make

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum

PALM KERNEL OIL PROCESSING PROCESS Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit Palm kernel Mechanical Pressing Unit Palm Nut Cracking & Shell Separation Unit Palm Nut is one of the byproduct of Palm Oil Extraction Plants.

Palm Kernel Oil Mill Plant Oil Expeller

Complete Turnkey Palm Kernel Oil Extraction Plant Installed in Latin America We have built a comprehensive business pattern which includes: 1. Turnkey Solutions with Customised Business Plan. 2. Equipment Designing and Manufacturing. 3. Factory Layout Design. 4. Installation and Commissioning. 5. Technical Training and All Around After Services. Fe...fao.org

Palm Kernel Oil Mill Plant - Oil Expeller

Oil Expeller / Oil Press. Palm kernels contain 45 ?50% oil content. To achieve maximum oil yield, it requires 2 stage pressing. The residual meal / cake obtained from the 1st pressing is transferred to the 2nd screw press for final crushing. After a 2 stage pressing, a residual oil of less than 7% is left in the Palm Kernel Cake (PKC) which