Optimization of Sesame Oil Extraction Process Conditions

Results obtained showed that higher rates of extraction were obtained when roasting sesame seed to 150˚C. The ratio of solvent to seeds found to be 6:1 gave higher extraction. Moreover, stirring

Optimization of Sesame Oil Extraction Process Conditions

In this study, the optimum operating conditions for sesame oil extraction were studied. N-hexane was used as a solvent. Different variables were investigated; sesame seeds particle sizes, ratio of solvent to seeds mass, contact time, stirring effect, roasting impact and extraction temperatures. Results obtained showed that higher rates of extraction were obtained when roasting sesame seed to

Optimization of Sesame Oil Extraction Process Conditions

In this study, the optimum operating conditions for sesame oil extraction were studied. N-hexane was used as a solvent. Different variables were investigated;

Optimization of Sesame Oil Extraction Process Conditions

In this study, the optimum operating conditions for sesame oil extraction were studied. N-hexane was used as a solvent. Different variables were investigated; sesame seeds particle sizes,...

Optimization of Sesame Oil Extraction Process Conditions

Solvent Extraction, Sesame Oil, Extraction Variables, Process Optimization 1. Introduction Sesame (Sesamum indicum L.) is cultivated in several

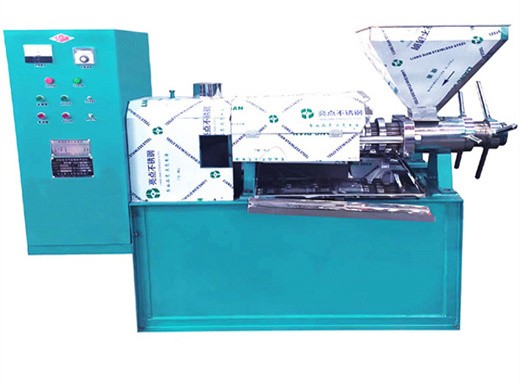

Optimization of Sesame Oil Extraction by Screw-Pressing at

Box-Behnken designs were used to optimize a process for sesame oil extraction by screw-pressing at low temperature (50 C). Experimental designs included seed moisture content (SMC), pressing speed (PS), and restriction die (RD) as the main processing parameters.

Optimization of Sesame Oil Extraction Process Conditions

This work is aimed to investigate the extraction of sesame seed (Sesamun indicum L.) oil using supercritical carbon dioxide and compressed propane as

Optimization of Sesame Oil Extraction Process Conditions

In this study, the optimum operating conditions for sesame oil extraction were studied. N-hexane was used as a solvent. Different variables were investigated; sesame seeds particle sizes, ratio of solvent to seeds mass, contact time, stirring effect, roasting impact and extraction temperatures.

Optimization of Sesame Oil Extraction by Screw-Pressing at

Whole (hulled) sesame seeds (Sesamum indicum L.) were obtained from commercial plantations located at Salta province, Argentina. Seeds were cleaned using an automated screen (EJR 2000 Zonytest®), packed in polypropylene bags, and stored at 5 °C until further use. In order to achieve the moisture content levels proposed in each experimental design,ResearchGate

Optimizing the extraction process of sesame seed's oil using

The conventional process for sesame oil extraction includes: (1) cleaning, (2) dehulling, (3) roasting, (4) grinding and (5) oil extraction, respectively (Fukuda and Namiki, 1988). Roasting is a critical stage which influences color, composition, and organoleptic qualities of the extracted oils as well as oxidative stability ( Yen and Shyu, 1989 ).