Improved canola oil expeller extraction using a pilot-scale

The fatty acid composition of canola oil expelled after steam or MW heating of flaked canola seed had a similar oleic acid content (18:1ω9) (57.9 vs 58.0%

Oilseed Presses - Penn State Extension

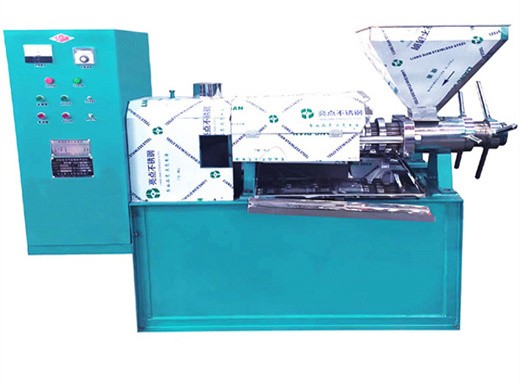

An oilseed press (Figure 1) is the heart of an oilseed pressing operation. Oilseed presses separate oilseeds such as sunflowers, canola, and soybeans into oil and oilseed meal. Pumpkin or grape seeds and brazil nuts are examples of materials that are less known and can be pressed for their oil in these machines.

Small Scale Oilseed Presses Extension

the oil content in the seed. Trial re-sults from this study show an aver-age of 24.2% net oil extraction across three crops (canola yielded 24.6% oil, soybean averaged 5.7% oil,

Canola Oil Processing Plant, Rapeseed Oil Press Machine

1. Small capacity, low investment, simple process, easy to operate, low labor intensity. 2. The rapeseed oil press machine integrates the functions of pressing and filtering. 3. Canola oil extraction plant is equipped with refining equipment to produce high-quality healthy oil. 4. Suitable for small oil mill or small rapeseed oil processing plant.

Cold Pressed Canola: A Biodiesel Option Minnesota

1 lb pressed canola contains 0.7 lb meal and 0.3 lb oil Assume: Value of canola seed $0.24/lb. Value of meal is $300/ton or $0.15/lb. Value of biodiesel produced is $3.00/gal.

Cold & hot canola oil press | rapeseed oil extraction machine

When using the canola oil press, the rapeseed should be put into the barrel. Then it is pressed by the hydraulic oil, and the process does not cause high temperature. After pressing, it should take out the cake or start pressing for the second time. Canola Oil Press Machinery Canola Oil Refining Process

Cold & hot canola oil press rapeseed oil extraction machine

After harvesting rapeseed, it usually takes the following steps to produce canola oil. Rapeseed cleaning and impurity removal → canola shelling → rapeseed roasting (optional) → rapeseed pressing by canola oil pressseedoilpress

Start a Small Scale Canola Oil Manufacturing Plant

The first step at the canola oil manufacturing plant is the pre-treatment of the rapeseed. The seeds initially need to be cleaned. Magnets are used to remove any metals, and impurities in the rapeseed can impede the extraction process when obtaining the canola oil, so they are screened and removed.

Canola Oil Processing Plant, Rapeseed Oil Press Machine

1. Small capacity, low investment, simple process, easy to operate, low labor intensity. 2. The rapeseed oil press machine integrates the functions of pressing

Canola seed oil press extraction test for production

A GFE customer wanted to do a quick test of a feedstock (Burnt canola). This is an uncut video of the entire test. Showing the ease and efficiency our oil pr...