Extraction of oil from grape seeds (Vitis vinifera L.) using

Grapeseed oil is generally obtained by pressing or solvent extraction (solid-liquid extraction) or by seed pressing; however, other extraction techniques,

Hydrothermal fractionation of grape seeds in subcritical water to

Based on the obtained data from aqueous ethanol extraction and anaerobic digestion, it was estimated that about 122.2 kg of grape seed oil, 23.8 kg of polyphenols, 109.3 m 3 of methane and 352.3 kg of organic fertilizer could be produced from 1 ton of grape seed by adopting the proposed strategy.

Grape seed oil extraction: Interest of supercritical fluid

Supercritical extraction (SFE) A typical extraction kinetic is presented in Fig. 3 (CO 2 pressure: 53.8 MPa, CO 2 temperature: 104 °C, CO 2 flow rate: 17 kg/h).

Hydrothermal fractionation of grape seeds in subcritical water to

The grape seeds are composed of several value added compounds, i.e. grape seed oil and polyphenols and the typical biomass components i.e. hemicellulose, cellulose and lignin. Aimed at fractionating the grape seeds into these fractions, a multi-step process based on the polarity of the compounds and the temperature resistance was designed.

Enhancement of the supercritical fluid extraction of grape seed oil

The supercritical fluid extraction of grape seed (Vitis vinifera L.) oil using carbon dioxide has been carried out at constant temperature (313.15 K) and solvent flow

Extraction of oil from grape seeds (Vitis vinifera L.) using recyclable

Grapeseed oil is generally obtained by pressing or solvent extraction (solid-liquid extraction) or by seed pressing; however, other extraction techniques, such as supercritical...

Recovery of grape seed oil by liquid and supercritical carbon

A novel green solvent, CO 2-expanded ethanol (CXE), was employed to extract oil from grape seeds, which is one of the main by-products generated by the

(PDF) Effects of subcritical water extraction and cultivar geographical

The Black Borgo帽a grape seed oil (BBGSO) and Quebranta grapes seed oil (QGSO) extractions with supercritical CO 2 were carried out with a multi-solvent extractor equipment Model 2802.000 (Top

Supercritical extraction of grape seed oil at

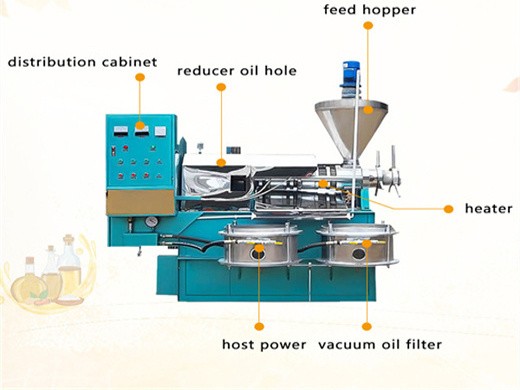

The plant has been designed considering treating the available grape seeds (≅3000 ton/year, Table 1).The system basically consists of three sections: one for the

Grape seed oil extraction: Interest of supercritical fluid extraction

2.1.2.2. SFE experimental procedure. The extractor vessel was first pre-heated at the desired temperature (for 45 to 60 min).Grounded grape seeds (200.0 卤 0.1 g) were introduced into the extractor vessel, above a PET filter (0,45 渭m, Sefar-Fyltis, France) to prevent the seed particles to clog the CO 2 circulation lines.