Low Cost Mini Palm Oil Mill Plant for 1-10 ton Production Line

For mini palm oil mill plant with 1~10 ton per day production output, the processing flow is relatively simple, including threshing, digesting and sterilizing, oil pressing and oil

Oil Palm Plantation & Milling - Wilmar International

However, the yield of an oil palm is relatively low at this stage. As the oil palm continues to mature, its yield increases and reaches peak production in years seven to 18 before gradually decreasing thereafter. The typical commercial lifespan of an oil palm is approximately 25 years.

Proessional palm oil processing machine manufacturer

1-10tph small scale palm oil press production line; 10-45tph medium scale palm oil press production line; 45-120tph large scale palm oil press production line; 1-1000tpd palm

Our Businesses | Sime Darby Plantation Berhad

The main feedstock for the production of oleochemicals are palm oil and palm kernel oil to produce intermediate products such as Fatty Acids, Fatty Alcohols, Esters and Surfactants, which are then used in the manufacturing of various non-food products as cosmetic, personal care, lubricant and biolubricant. We serve multinational customers globally.

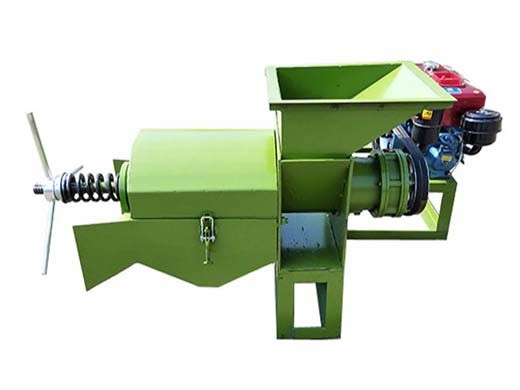

1-10 TPH small palm oil mill

1-10 TPH small palm oil mill. Palm fruit bunch is transported to factory by truck, the truck full of palm fruit through the door into mill, after the weighbridge weighting, driving to

Palm kernel oil refining production line- palm kernel oil

5. Palm kernel oil deodorising section: Removal of volatile components, mainly aldehydes and ketones, has a lower threshold to detect taste or odor. Deodorization is essentially a steam distillation process carried out at low pressure (2-6 mbar) and high temperature (180-220 degrees Celsius). Above is the palm kernel oil refining process

PRODUCT|Products information about palm oil extraction

1-10 TPH small palm oil mill Page 1 of 1 1 RELATED NEWS Read More Palm oil production process Date 10 12, 2017 Palm kernel oil refining production line Date 10

Palm Oil Processing Plant Cost for Fully Turnkey Oil Mill Plan

The equipment price is around $20,000~$30,000 for establishing a 5~10 ton/d small palm fruit oil milling factory. About $60,000 is needed as equipment investment to run a complete palm oil milling plant with capacity of 50 ton/day. If you want to build a complete oil mill plant including both palm fruit and palm kernel oil extraction, with

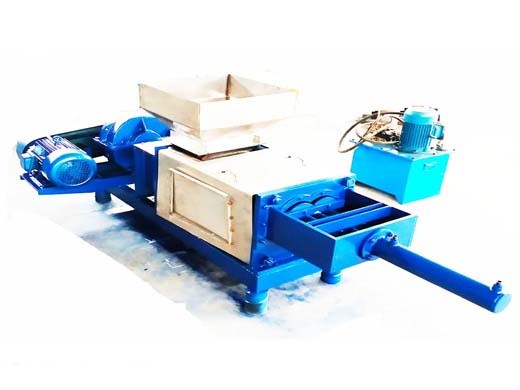

Palm Kernel Oil Production Line

The raw palm nut’s impurity should be cleaned firstly otherwise it would cause damage to the screw press machine. The magnetic selector is installed for removing metal debris, while the vibrating sieve is used for removal of sand, fines or other undesirable impurities. And the stones could be removed by gravity stoner.

FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil

Palm kernel recovery station assures high efficiency recovery process of palm kernel after palm oil pressing processing line. It prepares for further step palm kernel oil pressing process after splitter and crushing. Depericarper (splitter). Palm kernel separates from fibers through floating dry processing during crude palm oil processing machine.