Global Market Report: Palm Oil International Institute

VSS-compliant oil palm fruit accounted for at least 17% of total oil palm fruit production in 2016. Figure 1. Global oil palm fruit production trend 2008–201615,41 Note: VSSs

Improving Sustainability of Palm Oil Production by Increasing

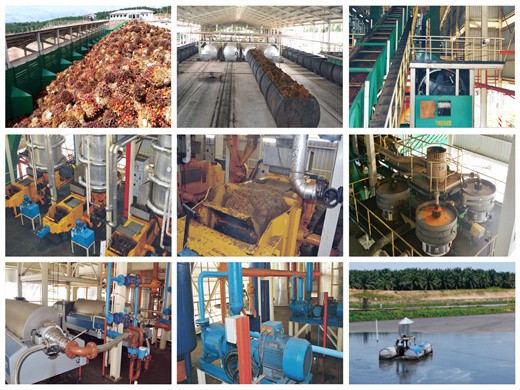

A palm oil mill typically adopts a solvent-free process that uses steam and water for oil extraction. Interestingly, the process to extract the oil from the palm fruitlets has remained relatively unchanged for the past 50 years. Figure 1 shows the block flow diagram of a typical palm oil mill for the production of crude palm oil. The major unit

Oil Palm by Product: How to Compute Its Cost of Production

Keywords:Cost of production, Crude Palm Oil (CPO), Palm Kernel (PK), computation methods, productive-output based, rendement-based. I. Introduction In Indonesia as the

Oil Palm by Product: How to Compute Its Cost of Production

There are two steps within cost of production computation for oil palm products, namely at the raw material level, and manufacturing level. At the raw material level, it has cost structure to produce FFB as follow : . Salary and wages . Maintenance . Seeding . Insect and desease control . Fertilizing . Harvest .

Global production volume palm kernel oil 2022/23 Statista

M. Shahbandeh. This statistic shows the production volume of palm kernel oil worldwide from 2012/13 to 2022/23. In 2021/22, the global production volume of

An overview of palm oil biomass for power generation sector

However, based on the updated data in Table 5, the power generation from palm oil biomass could be maximized to 4947 MW under 40% process efficiency of co-firing with coal power plant system that almost equivalent to the current power generation of 4100 MW at TNB Jana Manjung Power Plant (Bernama, 2019 ). TABLE 5.

Cost competitiveness of palm oil biodiesel production

6.8%. [ 41] The capital costs comprise cost for palm oil mill, conversion technologies for biomass residues and biodiesel plant. The capital cost of technology or

5. PALM KERNEL OIL EXTRACTION - Food and Agriculture Organization

The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying. The nut processing and oil extraction is undertaken in the dry season when the pressure to obtain raw materials has subsided. The traditional palm oil processing starts with the shelling of the palm nuts.

5. PALM KERNEL OIL EXTRACTION Food and Agriculture

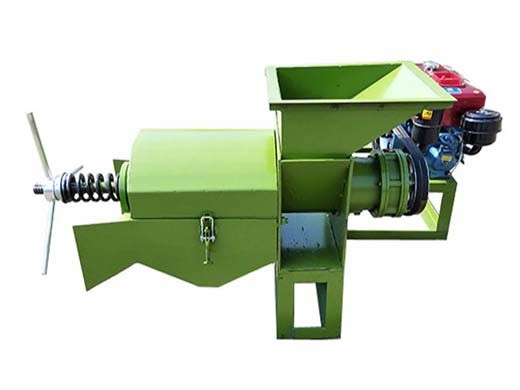

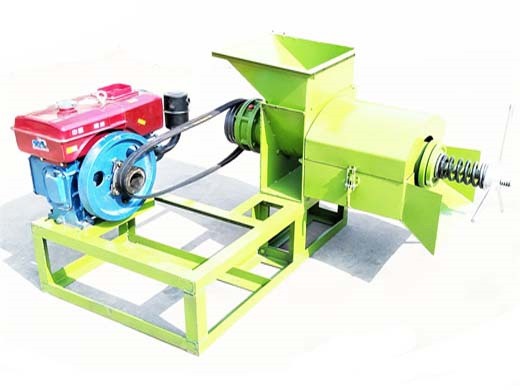

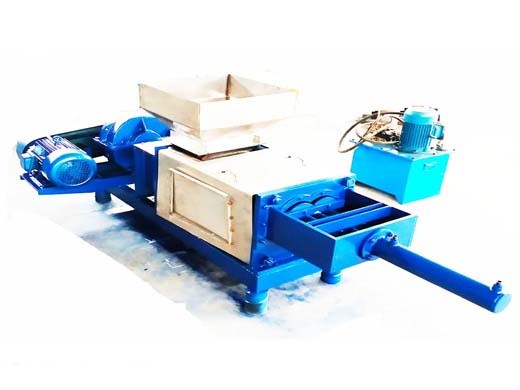

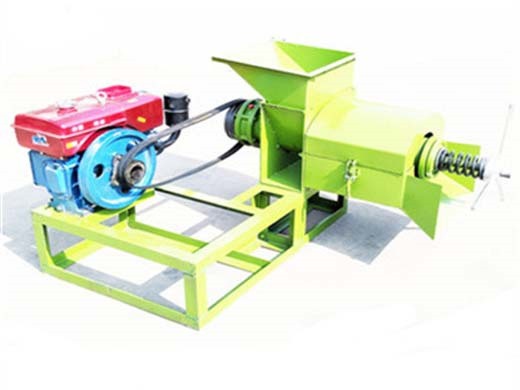

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder.

Palm Oil and Palm Kernel Oil Refining and Fractionation

The acidity of crude palm kernel oil can vary, depending on quality, from 2.0 to 6.0%. Poor crude palm kernel oil may show 1.0R/10Y (Lovibond 1? while good crude palm kernel oil may be no more than 0.4R/4Y (Lovibond 1?; this depends largely upon the way the kernels have been pressed and extracted, shipped, and stored (Patterson, 1992).