Extraction of corn germ oil with supercritical CO

The objective of this work was the extraction of corn germ oil using supercritical CO 2 as solvent and cosolvents addition. The experiments were performed

Corn Processing - Crown Iron Works

Corn germ is processed with the Model III Extractor. Desolventizing Once the oil has been removed by the solvent, the solvent must be removed from both the flakes and the corn oil. For the flakes, heat and steam are used to strip and recover the residual solvent. For the corn oil, a distillation system is used to recover the solvent.

Extraction of corn germ oil with supercritical CO2 and cosolvents

the supercritical extraction of corn germ oil at pressures of 34–55 MPa and constant temperature of 50 C. Experi-mental assays resulted in higher quality oil with a maxi-mum

Corn Oil: Composition, Processing, and Utilization

Most of the commercial corn oil is extracted from the germ and this is commonly known as 渃orn germ oil.?The germ from wet-milling operations (see Chapter 18) is recovered with up to 50% oil, which must be quickly processed because of its low microbiological and chemical stability.

Oil and protein recovery from corn germ: Extraction yield

This work aimed the recovery of oil and protein fractions from corn germ (CG) generated as a by-product during flour processing. Several oil extraction

Corn germ oil extraction with compressed propane compared

The extraction of corn germ oil was evaluated using pressurized propane as solvent in semi-batch process as an alternative approach to organic solvent extraction. The effect of temperature (20, 40, 60 C), pressure (20, 60, 100 bar), particle size and confinement time were studied.

Oil and protein recovery from corn germ: Extraction yield

Normal corn kernel contains about 3-6% of oil, of which 85% presents in the germ, followed by aleurone (12%) and endosperm (5%) (Rajendran et al., 2017). The

Corn germ-bran oils extracted with alcoholic solvents

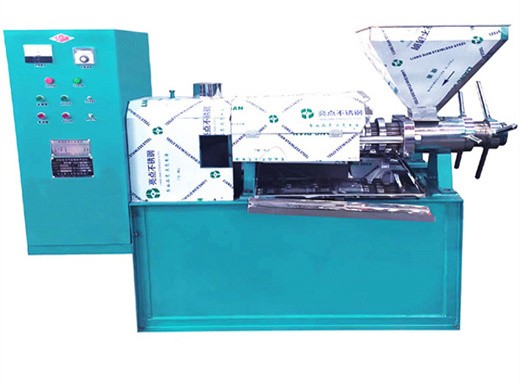

In the process of corn oil extraction, the germ passes through conditioning operations (heating, humidification and extrusion), to then be submitted to oil extraction by expeller (pre-pressing) and solvent extraction, with hexane being the solvent chosen by processors ( Moreau, 2005 ).

Corn Processing Crown Iron Works

Preparation. The first step of processing corn germ from wet milling or dry milling is to properly prepare the seed for oil removal. The seed is delivered clean;

Efficient and eco-friendly extraction of corn germ oil using

Corn germ oil was extracted from milled corn germ using diluted aqueous ethanol as solvent. Batch extractions were carried out in 500 mL glass reactor vessels which were series connected with a constant temperature water bath machine (MP-501 A, Shanghai Yiheng Scientific Instrument Co., Ltd., China).