NUT&KERNEL SEPARATION STATION Palm Oil Factory

Nut&Kernel Separation Station Firstly, the wet fiber and wet nut enter the cake breaker conveyor to be cracked, and mostly of the fiber should be separated by pneumatic fiber

NUT&KERNEL SEPARATION STATION - Palm Oil Factory

Nut&Kernel Separation Station Firstly, the wet fiber and wet nut enter the cake breaker conveyor to be cracked, and mostly of the fiber should be separated by pneumatic fiber depericarper System. The nut, little fiber and big impurity will be further separated by the polishing drum.

Nut and Kernel Separation : VIRIDIS Engineering

Palm Nut Fibre SeparatorNut SiloRipple MillsThe mixture of nut and fibre is dried first and then separated from each other in depericarper (nut & fibre separator). It is essential to separate palm nuts from the fibres. As fibres is light in weight, they are carried away by air flow, while nuts are fall into a rotary drum. The separated fibres are used in the boiler as fuel, the suppalmoilmillmachine

Nut and Kernel Separation : VIRIDIS Engineering

Nut and Kernel Separation Firstly, the wet fiber and wet nut enter the cake breaker conveyor to be cracked, and mostly of the fiber should be separated by pneumatic fiber depericarper System. The nut, little fiber and big impurity will be further separated by the polishing drum.

Nut&Kernel Separation Station Palm Oil Mill Machines

After dried moisture as 7%, the kernel will be conveyed to kernel storage bin for storage; Usually the dry kernel’s capacity ratio is 4% . So it should be collected until enough quantity, and then be sent to the palm kernel oil mill

Nut&Kernel Separation Station - Palm Oil Mill Machines

The separated nut should be sent to nut hopper through the pneumatic nut transport system, and then adopt the ripple mill to crack the nut, after cracking , most of the shell and kernel will be separated by cracked mixture separating system, and the rest of mixture of kernel & shell enter to the special clay bath separating system to separate

Nut&Kernel Separation Station Palm Oil Mill Machine

After dried moisture as 7%, the kernel will be conveyed to kernel storage bin for storage; Usually the dry kernel’s capacity ratio is 4% . So it should be collected until enough

Nut&Kernel Separation Station - Palm Oil Mill Machine Leading

Nut&Kernel Separation Station Firstly, the wet fiber and wet nut enter the cake breaker conveyor to be cracked, and mostly of the fiber should be separated by pneumatic fiber depericarper System. The nut, little fiber and big impurity will be further separated by the polishing drum.

Nut&Kernel Separation Station Palm Oil Plant

After dried moisture as 7%, the kernel will be conveyed to kernel storage bin for storage; Usually the dry kernel’s capacity ratio is 4% . So it should be collected until enough

Palm kernel & nut separation station - Palm oil extraction

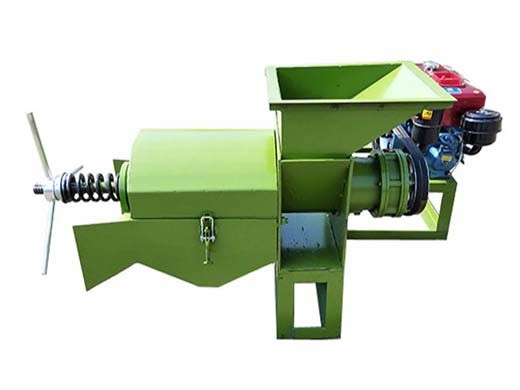

The palm nuts cracking machine is mainly applicable for dividing the palm kernels into the outer hard shell with high efficiency. The separating machine is for separating the palm nuts kernels from the cracked shells clearly and completely. There are two different types with capacity of 200-300kg/h and 1000kg/h as your choice.