Kinetics of soybean oil extraction using ethanol as

The data on the kinetics of extraction of soybean oil and free fatty acids using absolute and hydrous ethanol as solvents can be observed in Fig. 1, Fig. 2.Through the experimental data shown in Fig. 1 it is possible to verify that the oil contained in the

Soybean oil extraction and separation using switchable or expanded solvents

The extraction of soy oil from soybean flakes in industry requires large amounts of hexane solvent and results in significant losses and energy consumption during the distillative removal of the solvent. Hexanes and related hydrocarbon extractants are also becoming an environmental and health concern.

Oil extraction rates of soya bean using isopropyl

The average oil yields from soya brokens in 24 h were 71.8%, 74.8%, and 79.1% of the total oil, at the solvent flow rates of 4.15, 6.35, and 7.75 ml/min,

Economic feasibility analysis of soybean oil production by hexane

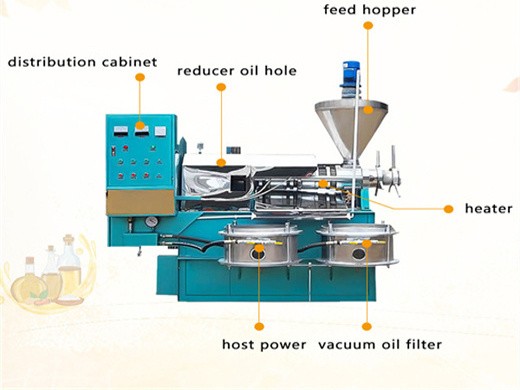

Crop preparation (handling), solvent extraction, degumming, desolvenization, and meal processing are main processes of the soybean oil hexane extraction process (Fig. 1). Crop preparation includes oil seed cleaning, cracking, dehulling, conditioning, and flaking.

Soybean oil extraction and separation using switchable

The extraction of soy oil from soybean flakes in industry requires large amounts of hexane solvent and results in significant losses and energy consumption during the distillative

Soybean Oil Extraction and Processing | SpringerLink

Soybeans are the dominant oilseed in both U.S. and world markets. During a typical year soybean production comprises over half the worldwide oilseed production ( Anonymous 1995 ). However, according to Dutton (1981) in the early 1940s, soybean oil was considered a poor quality oil, not suitable for food use, and more appropriate for use

Soybean oil extraction with ethanol from multiple-batch

The batch extraction sequence assumed to experimentally reproduce the 3-stage countercurrent extraction is demonstrated in Fig. 1 a, in which each circle

9.11.1 Vegetable Oil Processing - U.S. Environmental Protection Agency

The processfor soybeans typically consists of five steps: oilseed handling/elevator operations, preparation ofsoybeans for solvent extraction, solvent extraction and oil desolventizing, flake desolventizing, and oilrefining. Oilseed Handling/Elevator Operations -

Soybean oil extraction and separation using switchable

Replacement of hexane with a solvent less prone to losses is becoming a priority for the industry. Supercritical CO2 (scCO2) could be used but requires 500 bar for the most energy-efficient extraction of soy oil from soybeans (i.e. minimum energy cost per kg of extracted oil).2,3 Soybean oil is miscible with many other l

Solvent Extraction - AOCS

In the modern world, one major source of protein and vegetable oil is from oilseeds, particularly the soybean ?an abundant resource which is largely processed using solvent extraction, an efficient and reliable means to separate the high-protein meal solids from the high-energy edible oil.