Fat and oil processing Alfa Laval

Fat and oil processing. For decades Alfa Laval has been a leading supplier to producers of vegetable and animal fats and oils all over the world. Our specialized processing

Palm oil processing and production process | Alfa Laval

Reliable palm oil refining process technologies with complete plant solutions for bleaching and deodorizing Advancements to improve end-product quality while simultaneously boosting capacity, limiting loss and increasing yield Maximized energy efficiency for greater sustainability and reduced operational costs

POME treatment Alfa Laval

Sustainable management of palm oil mill effluent (POME) has never been more difficult. Traditional treatment methods place demands on millers, particularly in the face of strict

Palm oil milling equipment and machinery | | Alfa Laval

Our portfolio of equipment and palm oil mill machinery includes two- and three-phase decanters for efficient separation performance; nozzle separators for separation of sludge and increased oil recovery potential; purifier solutions based on a solids-ejecting disc stack separator; highly efficient cyclone desanders for the removal of fine sand

Good quality cooking palm oil refining machine edible oil

Good Quality Cooking Palm Oil Refining Machine Edible Oil Making Machine,Find Complete Details about Good Quality Cooking Palm Oil Refining

Palm oil - Andritz

Palm oil refinery (dry fractionation) Oil is kept warm and homogenized at about 70 C before crystallization begins in order to destroy any crystals that may have formed beforehand. Crystal formation and growth occurs as the oil is agitated, and chilled water circulation is used to control cooling until the oil reaches the required temperature

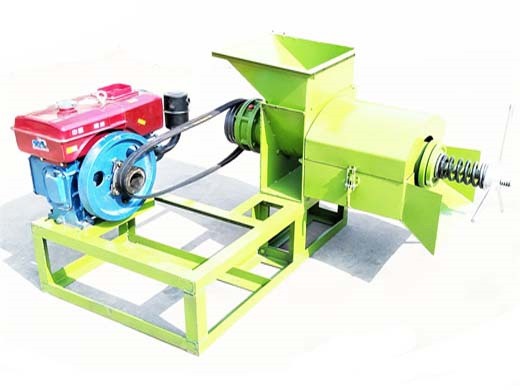

Palm Oil Processing Machine With Traditional Palm Fruit

We offer both small scale palm oil machine and large scale palm oil machine: Small size palm oil mill with the capacity of : 1TPH, 2TPH, 3TPH 5TPH Large and medium size

Food quality assurance of crude palm oil: a review on toxic

Generally, palm oil mills involve five basic unit operations: FFB sterilization, FFB stripping, digestion, oil extraction and oil clarification. FFBs are initially pre-treated in a high-temperature sterilization chamber to deactivate the lipolytic enzymes and loosen fruits ( Subramaniam et al., 2010 ).

Palm Oil Filling Machine: The Selection Guide VKPAK

Introduction The VK-LC automatic spindle screw capping machine is extremely flexible, is capable of capping accurately and rapidly any cap, such as trigger

What do Millennials think of palm oil? Nestl茅 investigates

However, rather that boycott the commodity, a good number of food manufacturers and retailers are pushing for sustainably produced, deforestation-free palm oil. Nestl茅 is one such company. Buying 榯housands of tons of it?every year to use in its food and beverage products, Nestl茅 is automatically implicated in the palm oil problem.