(PDF) Cold press in oil extraction. A review ResearchGate

The cold press oil production technique is a simple and environmentally friendly method without using chemicals, resulting in nutritious and safe products for

(PDF) Cold press in oil extraction. A review - ResearchGate

The cold press oil production technique is a simple and environmentally friendly method without using chemicals, resulting in nutritious and safe products for human health [4]. Vegetable oils

Oil Pressenergy Saving Stainless Steel Electric Oilpress

Oil Pressenergy Saving Stainless Steel Electric Oilpress/commercial Peanut Oil Press,Find Complete Details about Oil Pressenergy Saving Stainless Steel Electric

Cold pressed peanut (Arachis hypogaea L.) oil - ScienceDirect

Cold pressed peanut meal, also known as defatted peanut meal or pressed peanut meal, is a by-product of peanut oil extraction. It contains a high protein level (> 25%), and is white to creamy in color due to the mild thermal (< 60 C) treatment ( Zheng et al., 2013 ).

yemen advanced peanut oil press in soybean oil extraction

peanut oil press machine soybean oil extraction plant Besides, cold press peanut/sunflower/soybean oil expeller/coconut oil extraction machine is not only highly

Identification of species-specific peptide markers in cold-pressed oils

Table 1 presents the unique, species-specific peptide markers identified in coconut, evening primrose, flax, hemp, milk thistle, nigella, pumpkin, rapeseed, sesame, and sunflower cold-pressed oils

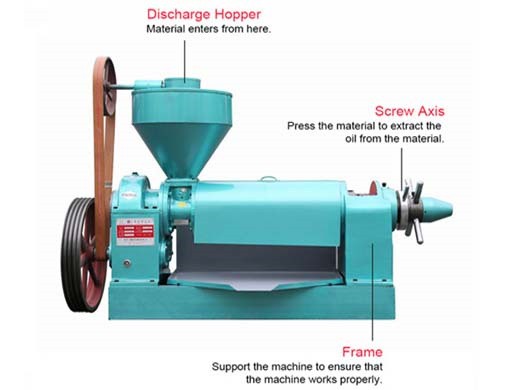

Peanut oil press machine,groundnut oil extraction

Raw material selection: Use peanuts with no mildew, or other sundries to squeeze oil. When there are many impurities, it should be screened first.Roasting/drying: Use a roaster or dryer to remove the moisture in the peanuts. The moisture after baking should keep at about 8.5%.Peanut oil pressing: Put the roasted peanuts at the entrance of the peanut oil press machine Raw material selection: Use peanuts with no mildew, or other sundries to squeeze oil. When there are many impurities, it should be screened first.Roasting/drying: Use a roaster or dryer to remove the moisture in the peanuts. The moisture after baking should keep at about 8.5%.Peanut oil pressing: Put the roasted peanuts at the entrance of the peanut oil press machine, and start the machine to automatically press the oil. At the same time, turn on the oil filter to clean...Filling: After filtering, use an oil filling machine to put peanut oil into special containers.展开选择时,新内容将添加到焦点当前区域上方

Peanut Oil Processing Technology - ScienceDirect

The conditioned peanut kernels are transported by a conveyor to the twin-screw press for cold pressing; the cold-pressed crude oil and cold-pressed peanut meal with low denaturation will be obtained. After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold-pressed peanut oil products ( Fig. 3.8 ).

Peanut Oil Press Machine Factory Direct Peanut Machine

2.Energy saving and labor saving.press 5kg raw materials just needs 1kilowatt-hour. 3.Cold and hot pressing,rich nutrition,pure natural oil,save refining costs.

Cold pressed peanut (Arachis hypogaea L.) oil | Request PDF - ResearchGate

Cold pressed peanut oil is composed mostly of unsaturated fatty acids, predominantly oleic and linoleic acids. Moreover, the oil is also rich in bioactive components such as tocopherols,...