Palm and Palm Kernel Oil Production and Processing

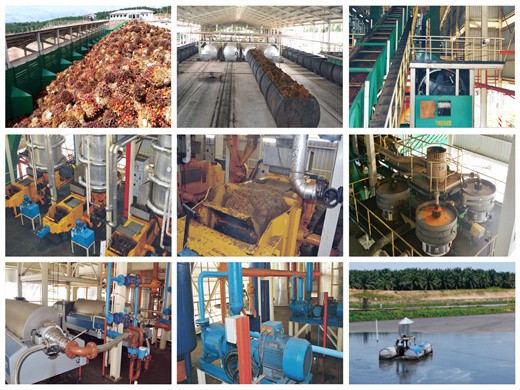

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding

BEST Palm Oil Processing Plant Design and Construction

BEST Palm Oil Processing Plant Design and Construction 1 2 3 Palm Oil Mill Plant (FFB) Palm Kernel Oil Extraction Palm Oil Refinery Plant Palm Oil Fractionation Supply BEST Palm Oil Processing Plant Oil palm is now the most important supplier of vegetable oil in the world.

BEST Palm Kernel Oil Extraction Plant|Oil Mill Plant Design

Palm Kernel Oil Extraction Plant. Palm kernel is an important kind of by-product from palm oil extraction plant. About 45%~48% of palm nut is kernel. The kernels contain about

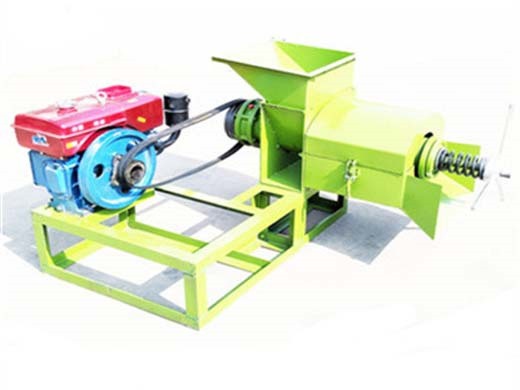

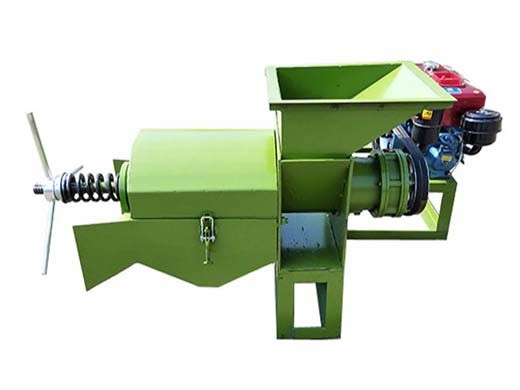

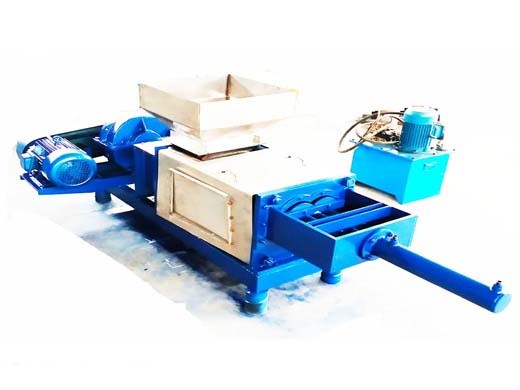

A plant design for mechnaical extraction of PKO

The design objective in this case is to redesign and fabricate a palm kernel oil extraction plant (mechanical) that will produce 200kg of palm kernel oil per day using palm kernel. In the extraction of palm kernel oil, many processes are involved namely: Traditional, solvent extraction and mechanical extraction methods.

BEST Palm Oil Processing Plant Design and Construction

Oil palm is now the most important supplier of vegetable oil in the world. Machinery can offer you the BEST customized palm oil processing solutions for

BEST Palm Kernel Oil Extraction Plant|Oil Mill Plant Design

Palm kernel is an important kind of by-product from palm oil extraction plant. About 45%~48% of palm nut is kernel. The kernels contain about 47%~50% by weight of oil. Palm kernel oil is quite different from palm oil in both characteristics and properties. However, it is more similar to coconut oil.

5. PALM KERNEL OIL EXTRACTION Food and Agriculture

MechanicalextractionSolvent ExtractionTraditional Method of Palm KernelextractionMechanical extraction processes are suitable for both small-and large- capacity operations. The three basic steps in these processes are (a)kernel pre-treatment, (b) screw-pressing, and (c) oil clarification. Diagram 2: Mechanical extractionof palm kernel oil. Line (A) is for direct screw-pressing without kernelpre-treatmentjagdishgroup

Palm Kernel Oil Extraction Expert - Oil Mill Plant

The direct solvent extraction process is used in larger plants. Production cost depends mainly on solvent loss and energy used in solvent recovery and pelletizing. However, oil recovery is more complete than in screw pressing. The third palm kernel oil extraction method uses pre-pressing followed by solvent extraction.

Palm Kernel Oil Extraction Plant Oil Extraction Equipment

Introduction To Palm Kernel Oil Extraction Technology. The fruit pulp contains 40 62% oil, and palm kernels contain 46-48% oil, which is chemically similar

(PDF) Development of Palm Oil Extraction System - ResearchGate

A vertical oil palm digester design was made to feed the screw press by gravity. Detailed design of the screw press hereby presented. Much emphasis was however made in the use of available local