Flushing procedure: Mobil SHC™ Aware™ H and Mobil SHC

hydraulic oil; flushing hydraulic oil; machine flushing; fluid contamination; exxonmobil marine Created Date 1/12/2018 12:06:46 PM

Cleaning and Flushing Basics for Hydraulic Systems

General Cleaning and Flushing Requirements To Achieve and Retain Satisfactory Initial Cleanliness Level 1. Chemically clean and treat internal systemsurfaces (components, tubes and hoses). 2. Perform hot oil flushing to reach target cleanliness level. 3. Inspect and verify that the cleanliness level was achieved. 4.

Hydraulic Flushing Systems Hydratron

Particulate Counter (Optional) The Inline Contamination Monitor provides real-time measures on the levels of contaminants present in hydraulic systems. The small device reports on saturation levels and has options for moisture and temperature if required. Also, it notifies

11 Simple Steps for Flushing a Hydraulic System | Machinery

Drain the flushing fluid as hot and as quickly as possible. Replace the filters and inspect/clean the reservoir again. Step 5 Fill the system to approximately 75 percent with the fluid to be used. Bleed/vent the pump. If the pump has a pressure relief or bypass, it should be wide open.

Hydraulic Oil Flushing Procedure “How To” White House

A hydraulic oil flushing procedure, when needed, helps remove contaminants and restores system performance. White House Products Has Solutions

Oil Flushing - Decontaminate Rotating & Hydraulic Equipment

The FS-500 is a fully integrated skid-mounted flushing and filtration unit specifically designed for quick set up and operation. The unit can provide controlled flow rates from 20 to 500 litres per minute for flushing, chemical cleaning, or filtering operations.

11 Simple Steps for Flushing a Hydraulic System

Step 5. Fill the system to approximately 75 percent with the fluid to be used. Bleed/vent the pump. If the pump has a pressure relief or bypass, it should be wide open. Run the pump for 15 seconds, then stop and let it sit for 45 seconds. Repeat this procedure a few times to prime

Hydraulic Flushing Systems - Hydratron

Hydraulic Flushing Systems - Hydratron Suitable Industries Marine Oil and Gas Aerospace Chemical Energy Food and Drink Robust design with wetted parts in stainless steel Turbulent flow for comprehensive flushing Manual or PLC controlled ATEX Compliance Available System Features 3 Micron Filtration

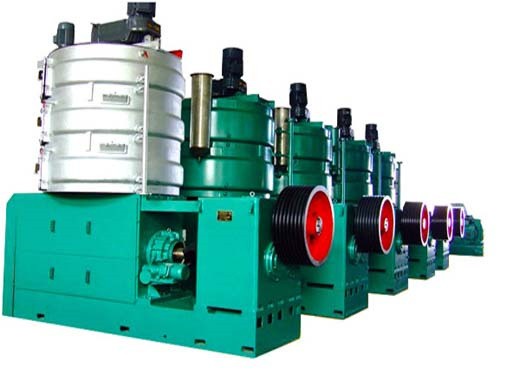

Hydraulic System Flushing Machine Manufacturer,

Hydraulic Flushing Systems Features: Flow rate: 20lpm, 50lpm, 100lpm Pressure : 10bar Design: Single Stage, two stage Power coated body Static Pressure Guage Electrical cable: 10m Inlet and outlet hose: 2 m each NAS class

Boost VR+ Hydraulic Oil Varnish Remover Solution | Fluitec

Removes Varnish and Sludge through Dissolution ?The unique chemistry of Boost VR+ increases oil solvency to re-solubilize deposits. Compatible with Your Lubricant ?Boost VR+ is compatible with all PAO-based and mineral lubricants. Easy to Use ?All you need to do is add Boost VR+ to the lube system one month before an oil change