palm oil extraction equipment in namibia

This second edition of Edible Oil Processing presents a valuable overview of the technology and applications behind the subject. 3.9.3 Olive pomace extraction 90. 3.10 Palm oil

palm oil line

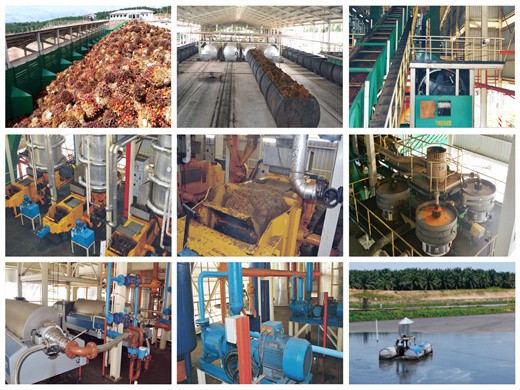

The purpose of clarification in palm oil manufacturing process is to remove impurities. The final crude palm oil will be storage in bulk in a tank. Palm kernel recoveyor After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts.

Palm Oil Processing Production Line

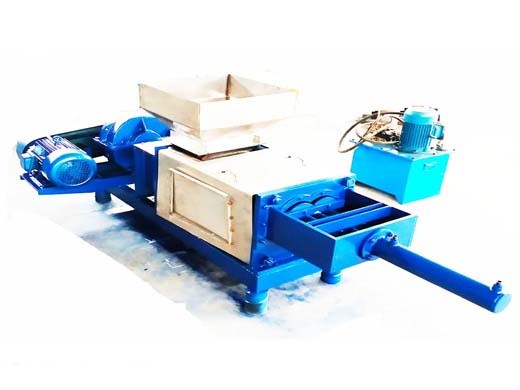

For small-scale palm processing farmers, Dingsheng Machine has designed single-screw and double-screw palm fruit oil press, which can process 1ton, 5 tons, 10 tons and 15

Palm Oil Production Line/Palm Oil Processing Plant - oil expeller

Palm oil production line includes three sections, palm oil pressing plant, palm oil refinery plant and palm oil fractionation plant. As the manufacturer of the palm oil production line, we can offer the whole line or part of the palm oil production line for different capacities with turnkey services. Pressing Plant Refinery Plant

Small-Scale Palm Oil Processing in Africa Food

2.3 Principles of preservation and processing methods. 3. PALM OIL PROCESSING. 3. 1 General processing description. 3.1.1 Bunch reception. 3.1.2 Threshing (removal of fruit

3. PALM OIL PROCESSING - Food and Agriculture Organization

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms.

Palm Oil Production Line/Palm Oil Processing Plant oil

It is mainly used for collecting the palm fruits. Palm fruits are weighed first after transporting to the plant, then they will be loaded on a slope. Under the slope, there are some cages to receive the palm fruits.

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum

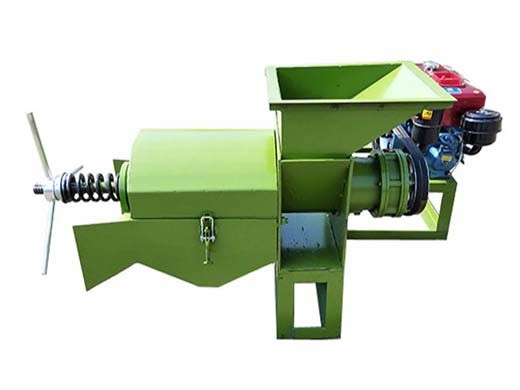

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing.

What machines will be used in palm oil production process?

If your daily capacity is between 1-5 tons/hour, 10-120 tons/hour or even larger, our engineer recommend the standard palm oil production line for you, which is

Hot Sell Palm Oil Pressing Machine, Screw Expeller at Factory

Screw oil pressing or expelling can be into hot pressing and cold pressing (read more about palm kernel oil pressing machine). Most palm oil production adopts hot pressing process. In hot pressing, the oil-bearing materials is cooked or heated before oil expelling. The cooking process has the following benefits: Destroy enzymes, anti-nutrient