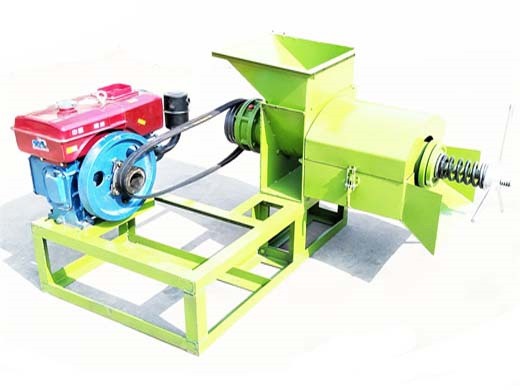

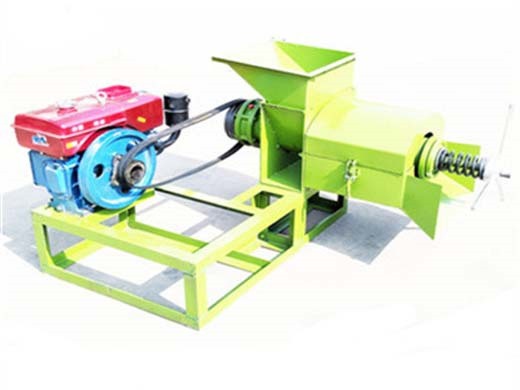

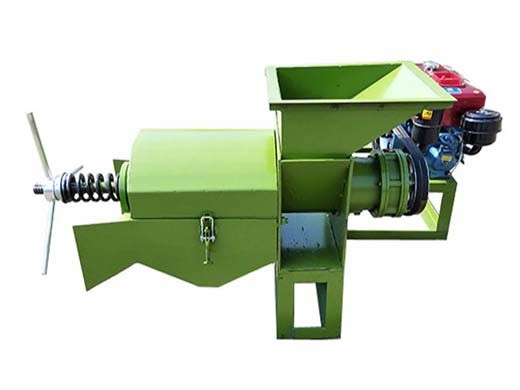

EFB Press EFB Treatment Machinery EFB Shredder

Shorter fibres improve burning efficiency in the boilers. Alternatively, for more effective application in composting or mulching, the Empty Fruit Bunch (EFB) Fiberiser can process the pressed Empty Fruit Bunch (EFB) into loose form fibre strands of 4 to 6 inches. 1) Squeezes out the juice

Empty Fruit Bunch EFB Press Machines - MBL

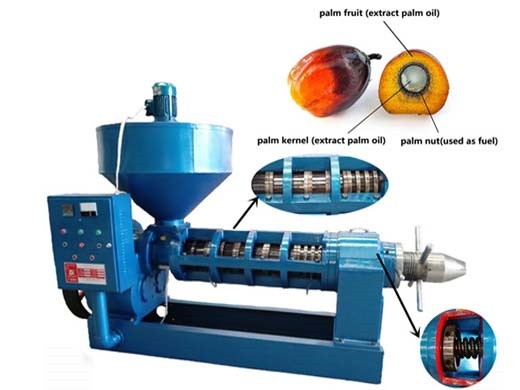

The palm expeller machines are used in a variety of processes to produce the palm kernel cake. These include kernel pre-treatment, grinding, flaking, steam conditioning, and screw pressing. During the pre-treatment process, the kernel is cleaned before it is ground to reduce its size.

Palm Oil Production Line Oil press machine Taixing

Palm Oil Production Line price in Malaysia FFB Process: After transporting the FFB to palm oil mill, the fruits will go to sterilizer by conveyor or palm

ISO Advanced technology palm oil production line /palm fruit

Palm Oil Processing Machine/palm oil production line . FFB Pressing Steps . 1. Load FFB into sterilizing tank, inject direct steam into it for high temperature sterilization.All fruits are heated when steam passes through bunches, reduce activation of bacterium and enzyme, avoid FFA from increasing,increase crude oil quality.

Big scale palm oil processing line,Palm kernel oil

Palm Kernel Press Processing Line Palm Oil Refinery and Fractionation Palm Fiber Production Line EFB Pressing Machine Palm Fruit Press Machine Sludge Centrifuge NEWS 292019/08 Our Palm Oil Mill Factory 45T/H 272019/

FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil

Palm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Process flow of palm oil pressing processing line:

Palm Oil Press Production Line

Raw Material:Fresh palm fruit bunch FFB(within 24 hours after picking) Capacity:5-120t/h FFB Final products: Crude Palm Oil (CPO) Production index: oil loss is less than or equal to 2%, moisture is less than 0.2%, free fatty acid

Palm oil press processing machine line plant

FFB Process: After transporting the FFB to palm oil mill, the fruits will go to sterilizer by conveyor or palm fruit cage. After separating palm fruits and palm bunch by thresher,Palm fruits will be conveyed to palm oil presser to get CPO. Palm bunch can be used as fertilizer or fuel. After pressing,we can get palm cake and palm nut.

FFB Fresh Fruit Palm Oil Press Production Line CPO

Complete Palm Oil Press Production Line Factory includes: 1. Palm oil mill process of Fresh fruit palm bunch reception Including palm fruit unloading, cleaning, storage

FFB Fresh Fruit Palm Oil Press Production Line CPO

After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.