Palm Kernel Solvent Extraction Mecpro

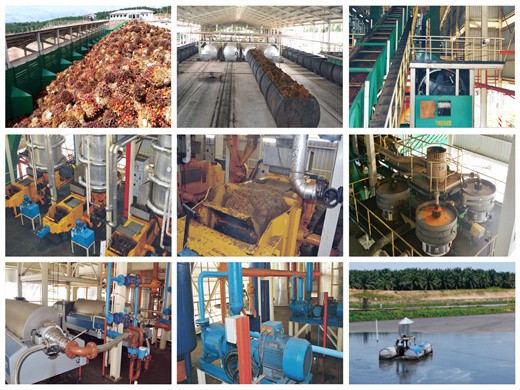

Palm kernel is the product of palm oil mills, which have a recovery efficiency of about 6 to 7% of the FFB processed. Currently, the seed is processed to extract the oil by pressing. In this process the quality of oil as well as the efficiency of extraction is limited. Mecpro has proposed a new method of direct solvent extraction using an

Palm Kernel Solvent Extraction - Mecpro

Solvent extraction The quality produced using the solvent extraction method is superior to mechanical extraction and will therefore enhance the profitability in processing of palm kernel. Further processing of the oil will reduce the chemical and energy consumption in the process.

Solvent Extraction Plant Eonmetall

Palm Fibre Oil Extraction Plant, a plant designed and equipped to extract the residual oil from palm-pressed fibre by means of solvent. A food grade solvent known as hexane is used to extract the remaining 5% 6% of residual crude palm oil (CPO) available

5. PALM KERNEL OIL EXTRACTION - Food and Agriculture Organization

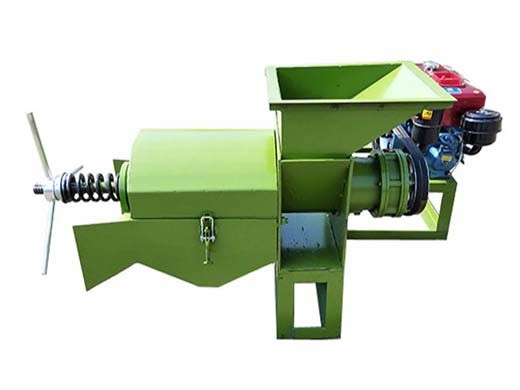

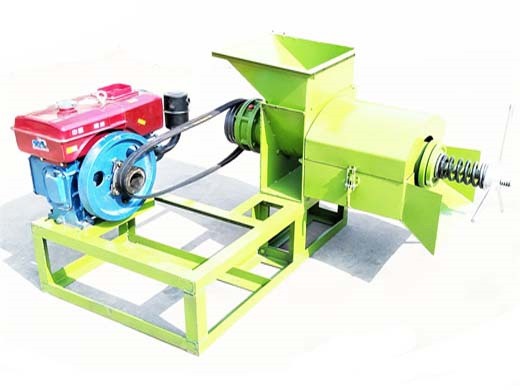

PALM KERNEL OIL EXTRACTION 5.1 Mechanical extraction Mechanical extraction processes are suitable for both small- and large- capacity operations. The three basic steps in these processes are (a) kernel pre-treatment, (b) screw-pressing, and (c) oil clarification. Diagram 2: Mechanical extraction of palm kernel oil.

Palm Kernel Solvent Extraction Plant Oil Expeller

Various processes are used for drying of Copra. Most of the farmers and villagers use sun drying as the major of process. Due to sun drying in open environment will attract the kernel or copra may stick with some dust and other impurities. Rotary drum cleaners or vibro screeners are used to remove fine dust from Copra.ScienceDirect

Solvent Extraction Plant ?Eonmetall

A food grade solvent known as hexane is used to extract the remaining 5% ?6% of residual crude palm oil (CPO) available in palm-pressed fibre, thereby enhancing oil extraction rate (OER) by 0.5%. Palm Kernel Oil Extraction (PKOE) Plant, is designed to extract the oil from kernel cake by means of solvent. This shall extract an additional 3% PKO.

Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of

Palm Kernel Solvent Extraction Plant - Oil Expeller

Method 2: Full press. First Pressing: The Kernel obtained after complete cleaning are send to screw presses of short length where the oil will be drained out. Cleaned Palm Kernel contains oil from 43% to 48% based on the size and breed of the seed. These kernels oil is extracted upto 28 ?30% and the balance oil 15 ?18% will be remained

Palm Kernel Oil Solvent Extraction Plant,Extraction Machine

The following is the main advantages of solvent extraction machine and plant: Fit for mass production of kernel oil extraction; High oil extraction rate, low oil residual in meal

Top Quality Palm Oil Solvent Extraction Plant for SALE

The palm oil solvent extraction plant is designed to extract oil directly from palm containing less than 20% oil, after flaking. Or it extracts oils from pre-pressed or fully pressed cake of palm containing more than 20% oil like sunflowers, peanuts, cotton seed, palm kernels, canola, copra, castor and a variety of other materials.