Palm Oil Processing Production Line

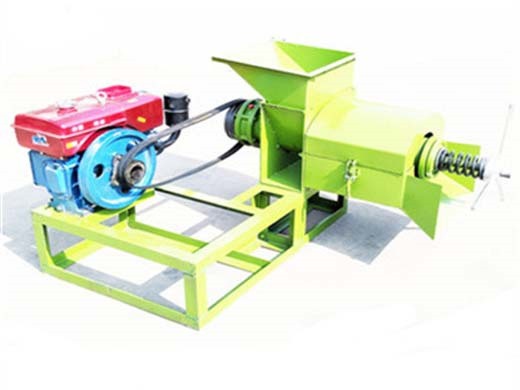

For small-scale palm processing farmers, Dingsheng Machine has designed single-screw and double-screw palm fruit oil press, which can process 1ton, 5 tons, 10 tons and 15

Palm oil processing and production process | Alfa Laval

Alfa Laval has worked alongside palm oil producers since the earliest days of the industry. More than 50 years?experience has gone into smart palm oil processing solutions for the entire supply chain ?milling, POME management, refining and more. Our complete range helps you increase yield while meeting increasingly strict environmental

Palm Kernel Oil Production Line -QI'E grain and oil

Section Introduction: The Oil Extraction for Palm Kernel mainly include 2 methods, Mechanical extaction and Solvent extraction.Mechanical extraction processes are suitable for both small- and large- capacity operations. The three basic steps in these processes are (a) kernel pre-treatment, (b)

Palm Oil Processing Production Line

Dingsheng Machine provides complete palm oil processing solutions and equipment, palm fruit and kernel processing, crude palm oil refining, fractionation, and wastewater treatment, help you maximize production and profitability while meeting increasingly stringent environmental requirements.

Palm Kernel Oil Production Line

The raw palm nut’s impurity should be cleaned firstly otherwise it would cause damage to the screw press machine. The magnetic selector is installed for removing metal debris, while the vibrating sieve is used for removal of sand, fines or other undesirable impurities. And the stones could be removed by gravity stoner.What is the purpose of refining palm kernel oil?palmoilline

Palm Kernel Oil Production Line - Seed Oil Press

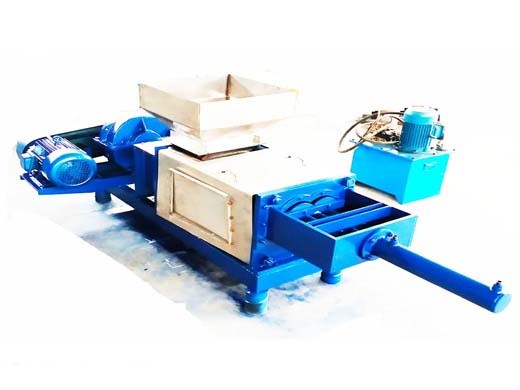

Our palm kernel oil production line capacity is 10-100 tons per day and its residual oil rate is 5%, and we provide you with palm kernel oil production and refining process design, manufacture, installation, commissioning and after-sales service if it is needed.

palm oil line

Oil palm is now the most important supplier of vegetable oil in the world. BTMA Machinery can offer you the BEST customized palm oil processing solutions for both fresh fruit

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum

PALM KERNEL OIL PROCESSING PROCESS Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit Palm kernel Mechanical Pressing Unit Palm Nut Cracking & Shell Separation Unit Palm Nut is one of the byproduct of Palm Oil Extraction Plants.

Factory recommended 200kg/h Plam Kernel Oil Processing

Model: 6YL-100 oil press Capacity: 200kg/h for oil seeds Power: 7.5kw (380V/50Hz/3p) or 15HP diesel engine Residue oil in cake: Less than 8% Size: 1320X540X1020mm

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

For large scale palm kernel oil production, there are two oil processing method, one is mechanical pressing, the other is solvent extraction. Mechanical pressing mainly adopts large scale oil press to squeeze oil, while solvent extraction utilizes solvents, such as hexane, to extract oil.