Palm oil mill effluent as the pretreatment solvent of oil palm

Pretreatment is an essential upstream process to deconstruct oil palm empty fruit bunch fiber (OPEFBF) prior to sugars production. This study aimed to investigate the efficiency

Liquid-hot-water pretreatment of palm-oil residues

Liquid Hot Water pretreatment (LHW) was evaluated on empty palm fruit bunch (EPFB) at 160?10 C, residence time of 0?0 min and solid loadings of 5?5% wt. The effects of these conditions on ethanol yield and potential profit were determined.

Pretreatment of empty fruit bunch from oil palm for fuel

This study evaluates the effects of some pretreatment processes to improve the enzymatic hydrolysis of oil palm empty fruit bunch (EFB) for ethanol production. The

Palm oil mill effluent as the pretreatment solvent of oil

During palm oil milling process, the yield of crude palm oil is about 20% of fresh fruit bunch by wet weight, while empty fruit bunch fiber is constituted up to 23% (Pradeepkumar et al., 2008). Besides, approximately 2.5?.8 tons of palm oil mill effluent (POME) will also be discharged for each ton of crude palm oil production (Wu et al., 2009).

Production of Bioethanol from Oil Palm Empty Fruit

This research aimed to elucidate the feasibility of ethanol production from oil palm empty fruit bunch (EFB) via acid impregnation-steam explosion as a

Reducing sugars and bioethanol production from oil palm empty

Exploring sustainable energy and chemical sources based on biomass has increased global interest. This study was focused on produce second-generation bioethanol using a new pretreatment process. The effectiveness of sodium hydroxide (NaOH) pretreatment on oil palm empty fruit bunch (OPEFB) for lignin removal, reducing sugar, and bioethanol production at low temperature and pressure was

(PDF) Techno-economic analysis of furfural production

Techno-economic analysis of furfural production with various pretreatment of oil palm empty fruit bunches using SuperPro Designer May 2021 IOP Conference

Process design, simulation, and techno-economic analysis

This study aims to propose a new process design, simulation, and techno-economic analysis of an integrated process plant that produces glucose and furfural from palm oil empty fruit bunches (EFB). In this work, an Aspen Plus-based simulation has been established to develop a process flow diagram of co-production of glucose and furfural along with the mass and energy balances. The plant

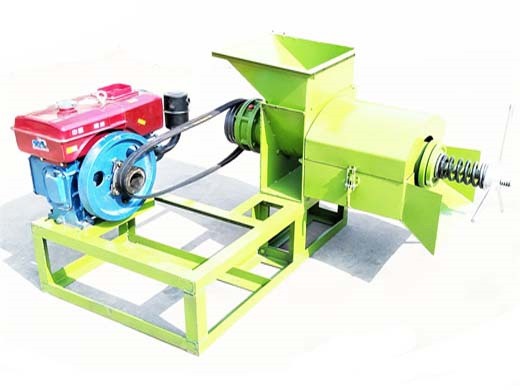

palm oil edible refining processing machine plant in uzbekistan

Uzbekistan 100T/D sunflower seed oil processing production In December 2018, China our company and Uzbekistan OOO "TOSHKENT

(PDF) Techno-economic analysis of furfural production

The purpose of this study was to investigate the feasibility of using steam at 0.28 MPa and 140 C generated from the palm oil mill boiler as a pretreatment to enhance the digestibility of EFB