Molecules Free Full-Text Headspace Solid-Phase

Peanut oil is favored by consumers due to its rich nutritional value and unique flavor. This study used headspace solid-phase microextraction (HS-SPME)

The Study of Ultrasound怉ssisted Enzymatic Extraction of Oil

To optimize this process, the effects of ultrasonic time (0?0 min), cellulase enzyme concentration (0?%) and pH (4?.5) are investigated on peanut oil extraction yield (EY) as well as the quality attributes of the extracted oil containing total phenolic content (TPC), peroxide value (PV), and color parameters of L, a, and b using

Effects of Extraction Methods on the Bioactivities

This study aimed to evaluate the effects of peanut varieties cultivated in Morocco (Virginia and Valencia) and extraction methods (cold press, CP; Soxhlet, Sox

Cold pressed peanut (Arachis hypogaea L.) oil - ScienceDirect

Cold pressed peanut meal, also known as defatted peanut meal or pressed peanut meal, is a by-product of peanut oil extraction. It contains a high protein level (> 25%), and is white to creamy in color due to the mild thermal (< 60 C) treatment ( Zheng et al., 2013 ).

Peanut Oil Processing Technology ScienceDirect

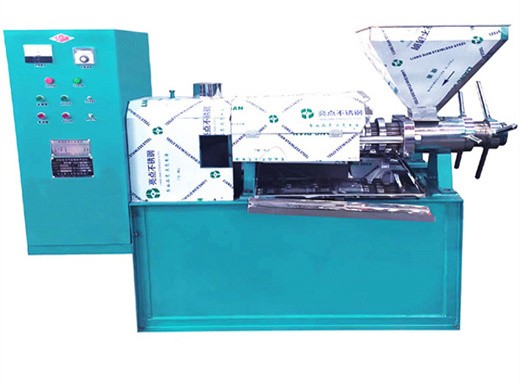

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the

Peanut Oil Processing Technology - ScienceDirect

This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

Bioactive Phytochemicals from Peanut Oil-Processing

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68–72% of the

Functional Proteins from Biovalorization of Peanut Meal

In countries like India and China, more than half of the produced peanuts (nearly 12?4 MMT) are processed using mechanical pressing or solvent extraction to produce edible oil. The residual matter obtained after oil extraction is called peanut meal, or peanut oilcake, and it contains about 47?5% protein (supplementary information 1).

Solvent extraction of oil from peanuts Google Patents

Publication Publication Date Title. CA1062727A 1979-09-18 Solvent extraction of oil from peanuts. US4359480A 1982-11-16 Production of a soybean meal. US4331695A 1982-05

Study on Extraction of Peanut Protein and Oil Bodies

As an innovative technology for extracting peanut protein and oil, aqueous enzymatic extraction has the advantages of having no organic solvent use, low energy consumption, and green and environmental protection and has mild reaction conditions and product safety [ 2 ].