Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of

Improving Sustainability of Palm Oil Production by Increasing

Palm oil is the world most-produced vegetable oil that is serving as an important source of food and energy for many developing and underdeveloped countries. The global demand for palm oil will continue to rise, owing to the growing population and economy. Presently, tremendous efforts have been devoted to improving the sustainability of palm oil production. One strategy is to improve the

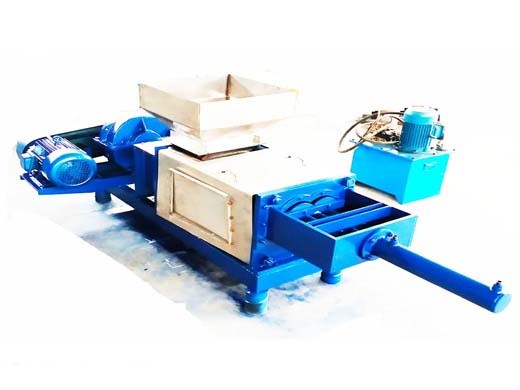

A plant design for mechnaical extraction of PKO

A Plant Design for Mechanical Extraction of Nmanu Aki (Palm Kernel Oil) Using Complete Pretreatment Process Gbasouzor Austin Ikechukwu, Member, IAENG, Okeke A. C.,

A plant design for mechnaical extraction of PKO

The process description for the mechanical extraction of 200kg of palm kernel oil per day is a follows: Before the commencement of the extraction proper, a laboratory test was carried out to determine the composition of palm kernel oil in a given quantity of palm kernel using solvent extraction method.

5. PALM KERNEL OIL EXTRACTION Food and Agriculture

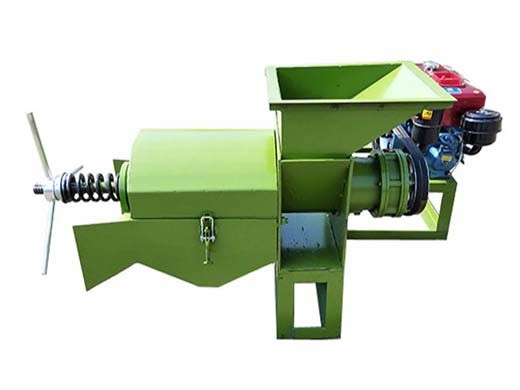

MechanicalextractionSolvent ExtractionTraditional Method of Palm Kernelextractionjagdishgroup

Palm and Palm Kernel Oil Production and Processing

The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18?3% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%. The simplified palm oil extraction process is shown in Fig. 8.3. The basic quality parameters for palm products are tabulated in Table 8-B.

Palm Kernel Oil Extraction Plant Oil Extraction Equipment

Introduction To Palm Kernel Oil Extraction Technology. The fruit pulp contains 40 62% oil, and palm kernels contain 46-48% oil, which is chemically similar

Palm Kernel Extraction : VIRIDIS Engineering

Palm Kernel Extraction The residue from the press consists of a mixture of fibre and palm nuts. The nuts are separated from the fibre by hand in the small-scale operations. The sorted fibre is covered and allowed to heat, using its own internal exothermic reactions, for about two or three days.

sunflower palm kernel oil extraction machine in malawi

Highly Efficient Palm Kernel Oil (PKO) Processing Machines Production Capacity: 100kg/h-5000kg/h Voltage: 220V/380V Dimension(L*W*H): 1800*1300*1680mm Oil type: Flax

ANNEX 1: Major manufacturers and designers of palm processing

Nova Technologies manufactures the 200 kg/hr vertical digester, spindle press and palm nutcracker. Bunch strippers may also be constructed for the threshing of fresh quartered fruit. Clarifiers are manufactured but there is not much demand for the decanter attachment. Processors prefer the open kettle clarifiers.