Degumming And Deacidification Palm Oil Mill Machine

Palm Oil Refining Degumming and Deacidification Section Introduction: Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the

Degumming And Deacidification - Palm Oil Mill Machine Leading

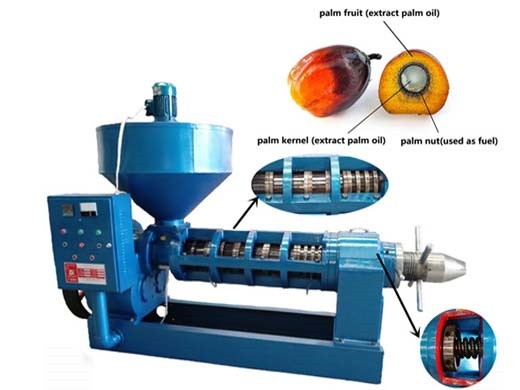

Dephosphorization & Degumming Equipment List: 1.Crude oil feed pump 2.Crude oil filter 3.Saving energy heat exchanger 4.Crude oil heater 5.Acidification of delay reaction tank 6.Phosphoric acid dosing pump 7.Multiple effect mixer Palm Kernel Oil Refining Decolorizing Section Inquiry Contact Us Tel: +86-027-8790 7188 Cell Phone: +86 156 0713 6506

Foods Free Full-Text Influence of the Degumming

The presence of glyceryl esters (GE) and 3-monochloropropane-1,2-diol esters (3-MCPDE) in refined, bleached, and deodorized (RBD) palm oil is severely concerning to the palm oil consumer. In the present study, the influence of the phosphoric acid

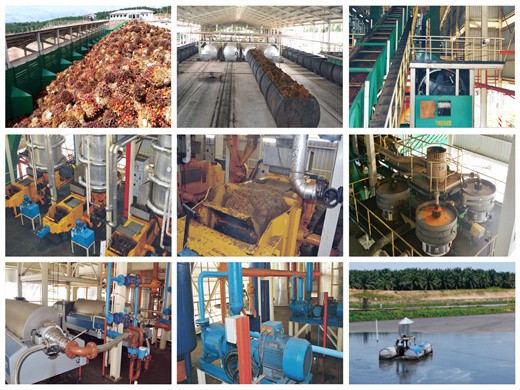

Palm oil processing and production process | Alfa Laval

For decades Alfa Laval has provided palm oil mills with efficient equipment to convert sterilized and pressed palm fruit into crude oil, playing a key part in shaping the design of today oil room. POME treatment To remain competitive, millers have to find the most cost effective and sustainable solution to deal with this harmful pollutant.

Palm Oil Refining Plant Palm Oil Mill Machine Leading

Palm Oil Refining Degumming and Deacidification Section Introduction: Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the remaining soap, add into the oil about 5~8% hot water, with

Palm Oil Refining Plant - Palm Oil Mill Machine Leading

Type: palm kernel oil refining Processing material: palm kernel Capacity: 30-1500T/D Major Equipment: degumming tank, heat exchanger, decolorization tower, deodorization tower Application: High efficiency oil refining method applicable for crude palm kernel oil, coconut oil Palm Kernel Oil Refining Process Flow Chart: Main process of the Palm

Degumming & Deacidification palm oil processing machine

Palm Oil Refining Degumming and Deacidification Section Introduction: Washing: there is still about 500ppm soap in the neutralized oil from the

DEGUMMING AND DEACIDIFICATION - Palm Oil Factory

Palm Oil Refining Degumming and Deacidification Section Introduction: Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the remaining soap, add into the oil about 5~8% hot water, with water temperature 3~5 鈩?higher than the oil generally.

DEGUMMING AND DEACIDIFICATION Palm Oil Factory

Palm Oil Refining Degumming and Deacidification Section Introduction: Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the

Degumming, deodorization, decolor and decidification small

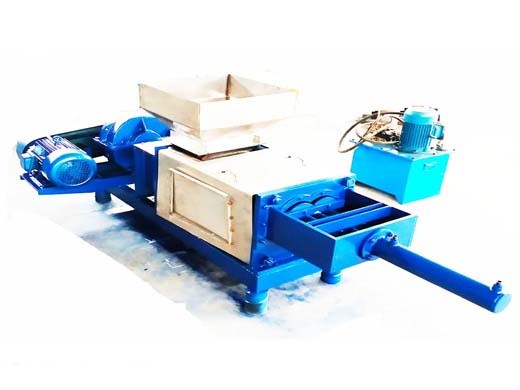

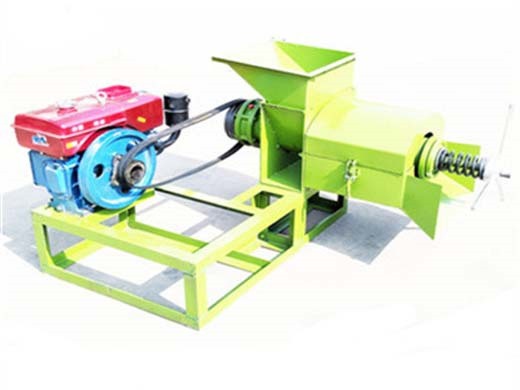

Degumming, deodorization, decolor and decidification small scale palm oil refining machinery Place of Origin:Shandong, China (Mainland) Certification:ISO 9001, CE Certificate Min.Order Quantity:1 Set Price:US $10,000 - 20,000/ Set Packaging Details:Standard Export Woodencase Suitable for Ocean Carriage