Extrusion/Expeller® Pressing as a Means of Processing

The experimentation of Nelson et al. in 1987 led to the use of extrusion as a means to pre-treat oilseeds for subsequent full pressing. Coarsely ground soybean was

Development of Domestic Purpose Hydraulic Press Oil Expeller

Design of a new type wool oil sprayer on domestic mixing gill. June 2008. J. Lei. This article introduces a new wool oil sprayer and its compounding system applied for mixing gill. The device is

(PDF) Design and Construction of Oil Expeller Press

The pressure on screw was determined & applied in the created meshed design in Ansys. From the achieved stress analysis it can be concluded that the screw

Mechanical Continuous Oil Expression from Oilseeds: A Review

The oil extraction by mechanical pressing is the most common method for continuous treatment of oleaginous seeds without solvent. Different types of presses can be used depending on the purpose (expeller, expander, and twin-screw extruder) and on the capacity range (3 kg h鈭? to 150 t day鈭?). At the laboratory scale, many authors have highlighted the effect of operating parameters (screw

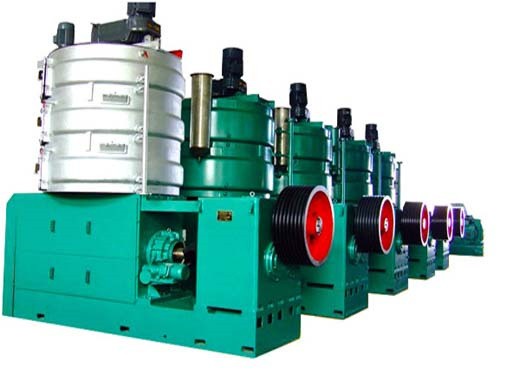

Expeller pressing

An expeller press is a screw-type machine that mainly presses oil seeds through a caged barrel-like cavity. Some other materials used with an expeller press include meat by-products, synthetic rubber and animal feeds. Raw materials enter one side of the press and waste products exit the other side. The machine uses friction and continuous pressure from the screw drive to move and compress the seed material. The oil seeps through small openings that do not allow seed fiber s

Expeller pressing

An expeller press is a screw-type machine that mainly presses oil seeds through a caged barrel-like cavity. Some other materials used with an expeller press include meat by-products, synthetic rubber and animal feeds. Raw materials enter one side of the press and waste products exit the other side.

CHAPTER 3 Food and Agriculture Organization

It replaces the historical method for the batchwise extraction of oil by mechanical or hydraulic pressing. The expeller (Fig. 7) consists of a screw (or worm), rotating inside a

Mechanical Extraction Processing Technology for Biodiesel

Expeller presses range in capacity from less than 1 ton to over 50 tons per day. The mechanical expeller press has six elements: the main worm shaft and worm, cage bars, drainage barrel, choke mechanism, motor transmission and bearings, and the loading system.

History of Human Powered Oil Expeller: A Literature Review

This paper covers the form and existence of oil expeller as well as manual methods from last decades. It delivers a vibrant introduction to both traditional

The choke mechanism Machine Capacity: The theoretical

Production of vegetable oil is generally determined by the extraction methods that are based on the four main principles visa: traditional wet rendering process, hydraulic press, solvent