Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

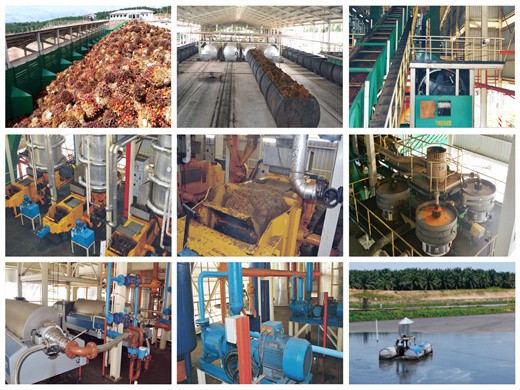

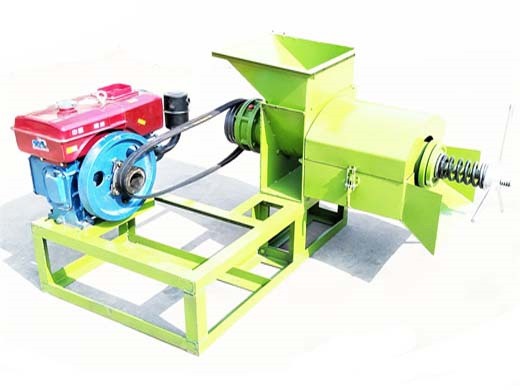

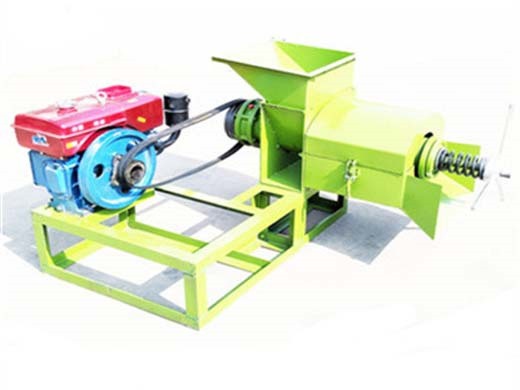

Palm Kernel Oil Processing Plant and Cost. Small Scale Palm Kernel Oil Press Machine and Plant; For small scale palm kernel oil production business, the screw palm kernel

3. PALM OIL PROCESSING - Food and Agriculture Organization

The stages in this process comprise grinding the kernels into small particles, heating (cooking), and extracting the oil using an oilseed expeller or petroleum-derived solvent. The oil then requires clarification in a filter press or by sedimentation.

Palm kernel oil processing machine Palm oil extraction machine

The pretreatment and pressing process of palm kernel oil have a great influence on oil extraction efficiency and production cost. Before entering the palm kernel oil press, the palm kernel undergoes a series of treatments to make its temperature and humidity reach the appropriate level for pressing. Palm kernel oil pressing Wikipedia

Palm and Palm Kernel Oil Production and Processing

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding period. In the case of Indonesia, the industry has grown rapidly with the oil palm plantation expanding

Palm kernel oil

Palm kernel oil is an edible plant oil derived from the kernel of the oil palm tree Elaeis guineensis. It is related to other two edible oils: palm oil, extracted from the fruit pulp of the oil palm, and coconut oil, extracted from the kernel of the coconut. Palm kernel oil, palm oil, and coconut oil are three of the few highly saturated vegetable fats; these oils give the name to the 16-carbon saturated fatty acid palmitic acid that they contain.

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

For large scale palm kernel oil production, there are two oil processing method, one is mechanical pressing, the other is solvent extraction. Mechanical pressing mainly adopts large scale oil press to squeeze oil, while solvent extraction utilizes solvents, such as hexane, to extract oil.

Palm Kernel Oil Manufacturing Process With Flowchart

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum

PALM KERNEL OIL PROCESSING PROCESS Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit Palm kernel Mechanical Pressing Unit Palm Nut Cracking & Shell Separation Unit Palm Nut is one of the byproduct of Palm Oil Extraction Plants.

Palm oil refining machine Palm oil processing machine

Palm oil / palm kernel oil refining machine (1-1000tpd) After palm oil extraction process and palm kernel oil extraction process, we can get crude palm oil and crude palm kernel oil. But if you want to get RBD

Palm Oil Production Line

Palm kernel is an important kind of by-product from palm oil extraction plant. About 45%~48% of palm nut is kernel. The kernels contain about 47%~50% by weight of oil. PALM OIL REFINERY PLANT Palm oil refinery palnt offer turnkey palm oil refinery plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing.